This post is also available in: 简体中文 (Chinese (Simplified))

Two decades ago in Raahe, Finland, Primetals Technologies ushered in a new era of quality in continuous casting with the first installation of Dynagap Soft Reduction— now active in 300 casting strands worldwide.

The town of Raahe, founded in 1649 by an emissary of the Swedish crown, is located on the shores of Finland’s Northern Ostrobothnia region. It has a busy port, a healthy amount of tourism and a well-preserved wooden Old Town.

This description might fit many other northern towns—but Raahe has something special going for it: It has long been home to a steely-eyed industrial avant-garde. As part of a strategic-development program, the Finnish government had decided in the late 1950s to strengthen economic development in the country’s central and northern regions by establishing a steel industry there. The goal was to meet growing demand for steel in Finland’s flourishing shipbuilding industry and to lure professionals from the country’s south to better populate the north. As one of the first steelmaking operations worldwide, the Raahe plant achieved a continuous casting rate of 100% on its vertical casters in 1967. Two bow-type casters were added at a later stage. And in 1997, the plant was again the site of a world first: The start-up of a new continuous caster with a fully dynamic strand guide system, allowing operators to adjust the roll gap at the push of a button and increasing slab quality at the same time. It was the first installation of Primetals Technologies’ DynaGap Soft Reduction technology, which has since been continually refined and is now a part of almost 300 casting strands worldwide.

Meeting the old crew

In the fall of 2017—exactly 20 years after completing that pioneering installation—some of the men from the original teams sit down at a table in the plant’s day room to celebrate the anniversary. Over a cup of coffee, they introduce themselves in turn, talking about their current occupations. There’s Jarkko Matkala, the site manager, Jarno Pirinen, the head of steelmaking at Raahe, and Michael Stiftinger, now in charge of Mechatronics at Primetals Technologies. “My name is Tauno Haapakangas. I work in the forest now—with my Husqvarna”, says the last of the men with a smile, as the group cracks up laughing. Mr. Haapakangas has been out of the steelmaking game for quite a while now, spending some of his newfound spare time cutting spruce and birch trees for timber with his chainsaw. Back in the day, he managed the caster replacement project for the state-owned Rautaruukki corporation, which was undergoing privatization in the 1990s and is now part of Swedish SSAB. Across the table sits his counterpart from Primetals Technologies, Karl Pirner. He, too, retired a few years ago, but vividly remembers the years he spent in Finland, living in a brightly colored wooden house not far from the plant and working long hours in the short Finnish winter days, where at times the sun would set while his team was still having lunch.

Looking back: The original problem

In 1995, Rautaruukki had decided to begin replacing its three vertical casters with a new one featuring a straight mold and liquid core bending and straightening. The driving force behind the decision was not so much the desire for higher-quality slabs—although that was a factor, too. Rather, it was the plant’s just-in-time production schedules: They demanded that the casters produce slabs of up to eight different thicknesses, requiring manual adjustment of the roll gap several times a day. Each one of these changes meant up to two hours of standstill and onerous labor for the crew. Rautaruukki quite simply needed something to take that pain away.

As it turned out, this “something” was at the very same time being cooked up in a university mechatronics lab in Linz, Austria.

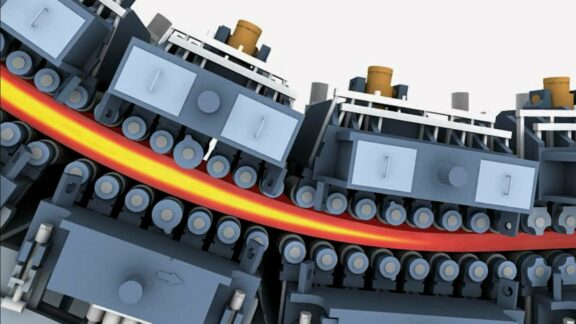

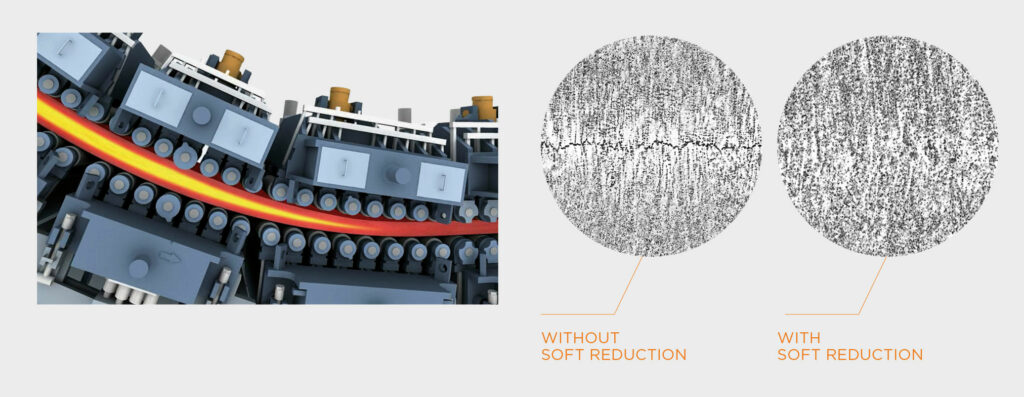

Since steel does not solidify at a fixed temperature, but over a temperature interval, slabs in the casting process have a “mushy region” at the center, where the steel is neither entirely liquid nor solid. If conditions aren’t exactly right, “segregation” occurs in this center part of the slab: Because of thermal contraction near the point of final solidification, there is a flow of residual melt toward the center. And since that residual melt often contains high levels of carbon, sulfur, and other kinds of impurities, the center segregates from the rest of the material, creating undesirable material properties in the resulting product. One way to minimize center segregation is to compensate the thermal contraction by intentional thickness reduction near the point of solidification. This method is called soft reduction.

Minimizing center segregation

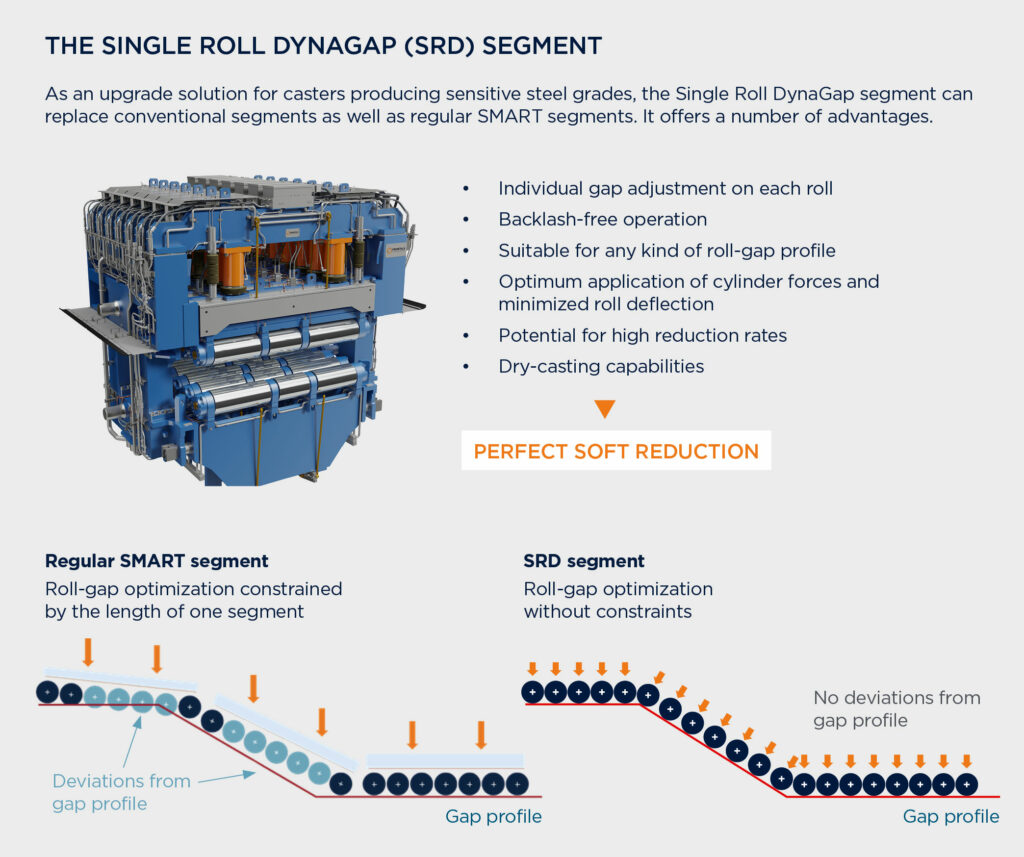

The genius of DynaGap Soft Reduction is that the technology calculates the ideal roll-gap set points with online process models, taking into account the temperature field in the strand and employing a steel-grade dependent gap practice. Even in varying casting conditions, the pressure is always applied just at the right point by hydraulically adjustable SMART segments in the casting strand. Since its pioneering first application in 1997, DynaGap has been continually refined, culminating in today’s DynaGap 3D and Single-Roll DynaGap, which takes precision in soft reduction to the next level: from the segment to individual rolls.

Directly from the mechatronics lab

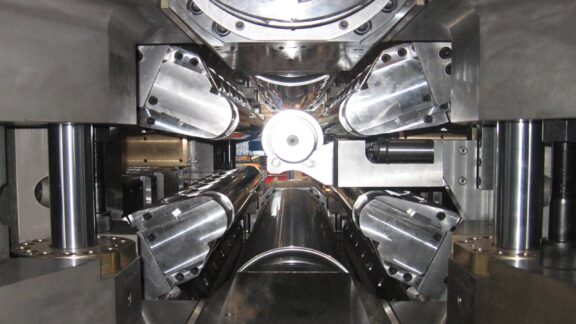

Up until that point, hydraulic adjustment in the roll gap had only been possible using servo hydraulics—a technology far too costly and way too prone to malfunctioning in dusty environments to be employed in regular continuous casting plants. Researchers and engineers in Linz, working with continuous casting experts from Primetals Technologies (at the time VAI), realized that a simpler setup involving more robust on/off valves could do the job just as well—and prove to be a lot more durable in the environment of a casting facility. Combining this hardware with position sensors would dramatically reduce the need for manual labor and downtimes when adjusting the roll gap. Thickness could be changed remotely at the push of a button. And the system would have a huge, additional benefit: adding advanced automation and process models, the dynamically adjustable roll segments would significantly increase internal slab quality.

A bold move

When Rautaruukki engineers learned of the technology in the run-up to a continuous casting conference (CCC) in Linz, they were convinced on the spot: This was the solution to their long-standing problem. After a short process of negotiations, the Finnish steel producer placed the order in a bold move and a grand gesture of trust. After all, the hydraulic setup had until that point hardly been tested outside of the lab.

The new, highly flexible continuous caster was to replace three individual vertical casters, operating at different casting thicknesses. In addition to the pioneering dynamic strand-guide system, it would also include the first hydraulic oscillator in Scandinavia. And because the caster had to be integrated into a tight existing structure, the order also included new ladle and tundish turrets to fit into the available space. “Some of the documentation of pre-existing equipment was available only in Russian,” recalls Karl Pirner, the Primetals Technologies project lead, “A testament to Finland’s long-standing friendly relations with its eastern neighbor.” Work started in 1996 and was concluded successfully when the caster was started up on December 15, 1997—right on schedule. Performance and availability were excellent from the start, as the machine cast slabs first in three, then four different thicknesses per day, drastically cutting the amount of manual labor required for the roll-gap changes. Careful inspection of numerous slabs by the Rautaruukki quality department showed internal quality to be excellent from the get-go. With news about the success in Finland spreading, new installations of DynaGap at other sites were soon to follow: ILVA, voestalpine Stahl, Bethlehem Steel, POSCO, and Outokumpu were among the early adopters. Today, DynaGap Soft Reduction is operating in close to 300 casting strands all over the world.

Automating changes in the roll gap with hydraulically adjustable SMART segments was a giant leap forward in terms of efficiency and product quality in continuous casting. But quite naturally, segment-level control of the roll gap allows only one gap setting across all the rolls contained in a segment. Consequently, it hits the point of solidification only by some measure of approximation. For sensitive steel grades, this might not be enough.

That is why Primetals Technologies has developed the Single Roll DynaGap (SRD) segment. Each individual roll is controlled by its own dedicated hydraulic cylinders. With high-quality data from the DynaPhase and Dynacs 3D secondary cooling models, the SRD segment can hit the exact point in the strand where dynamic soft reduction has to be applied for maximum center quality. The segment is interchangeable with DynaGap SMART segments as well as with other segment designs and can thus easily be integrated into existing setups. SRD segments have already been deployed in production—at the Ternium integrated steel works in Santa Cruz, Brazil. In light of the excellent results, the company recently decided to equip an additional strand with the technology.