This post is also available in: 简体中文 (Chinese (Simplified))

Today’s steel producers face the dual challenge of ensuring on-time delivery and meeting ever-demanding product requirements, while also running a lean operation. The day-to-day management of a long-rolling plant requires continuous optimization of both operating and business practices and Industry 4.0 is making an impact.

Imagine a long-rolling facility designed to address these competing demands, a plant where individual pieces of equipment communicate with each other, where sensor information can be used not only for control purposes but also to monitor the condition of the equipment, where models are used to verify the process remains within working limits, and where the equipment alerts operators whenever maintenance is required.

Every mill owner’s goal is the highest utilization possible for their investment. New data from devices such as smart sensors, advances in predictive maintenance, and condition monitoring systems can take a long-rolling mill a step closer to that goal. Imagine stand no. 1 informing stand no. 2 about the product’s status, and then specifying the actions required from stand no. 2 based on the rolling condition of stand no. 1. Imagine the roughing mill communicating with the intermediate mill.

Revolutionary developments

This ideal long-rolling operation may be possible in the not-too-distant future. The ongoing evolution in technology through data collection, communication, Internet of Things, control techniques, and smart sensors is generating more information than ever before. Acting on informed data analysis will initially advance both control and monitoring of plant performance. In the longer term, however, it will revolutionize long-rolling mills worldwide and optimize their entire value chain, enabling improved and more flexible production.

Today, there is a traditional horizontal and vertical integration of mill-control and supervisory systems. But with these future changes in technology, communication will occur seamlessly within a plant, allowing long-rolling-mill managers to instantly respond to data supplied by all sensors, machines, and processors, using the Internet of Things as a major pathway.

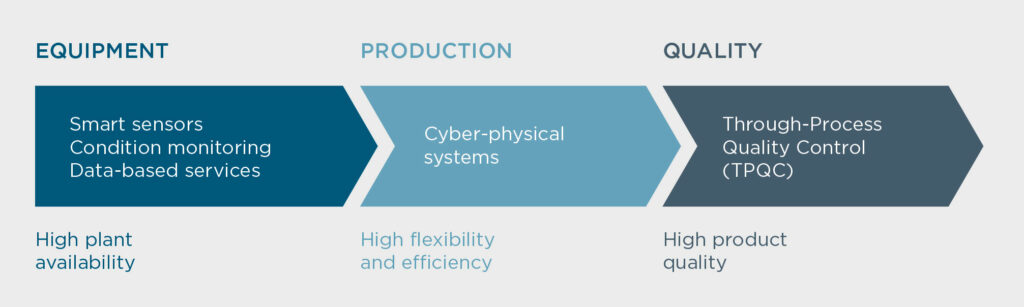

There is a great deal of interest within the long-rolling industry in what has been labelled Industry 4.0, digitalization, or the Smart Factory. While the specifics of each plant’s requirements differ from one long-rolling mill to another, the packages supplied within the Industry 4.0 portfolio range from smart sensors, mechatronics solutions, and robotics, to cyber physical models, maintenance systems, and full plant production. Designed to present immediate customer value generated from improved productivity, quality, and flexibility, the portfolio elements access the information available through sophisticated real-time data analysis to understand and optimize a mill’s process.

A bundle of new technologies

It is important to recognize that Industry 4.0 is not one product but a group of technological, process, and maintenance packages to support the transition of a long-rolling plant so that it can meet the future requirements of plant digitalization.

Digitalization started years ago and will not end anytime soon. Suppliers will actively assist plant operators in the digital transformation of their production plants by developing a roadmap of portfolio elements and services based on each plant’s short- and long-term requirements and strategy. Implementation will most likely occur through phased, small modernization projects, to minimize impact on ongoing production.

As a partner and supplier to the steel industry, Primetals Technologies continuously develops new technological functions and packages for long-rolling mills in close alignment with key customers, to increase overall productivity and to improve quality, mill flexibility, and mill efficiency. These relationships enable development teams to understand the challenges mill owners face, so that they can provide the tools to support the anticipated growth in technological possibilities and the advancements in future long-rolling plants. Elements of this vision already exist. The long-rolling “Smart Factory” will include numerous components to generate data, as well as systems to analyze the new information.

Smart sensors

As a general category, smart sensors provide additional information on the state of equipment or the production process itself. They either directly measure physical values or use existing measurements to indirectly calculate additional information. They enable the implementation of advanced automatic functions, process models, and condition monitoring—and they can communicate this information to anyone at any time.

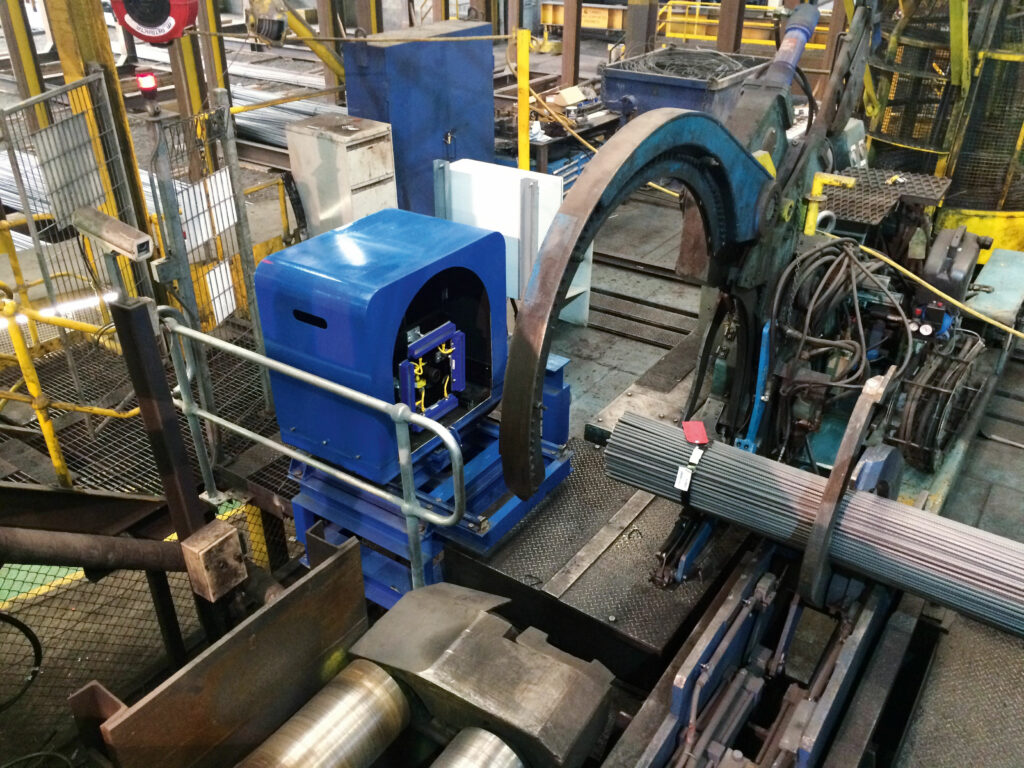

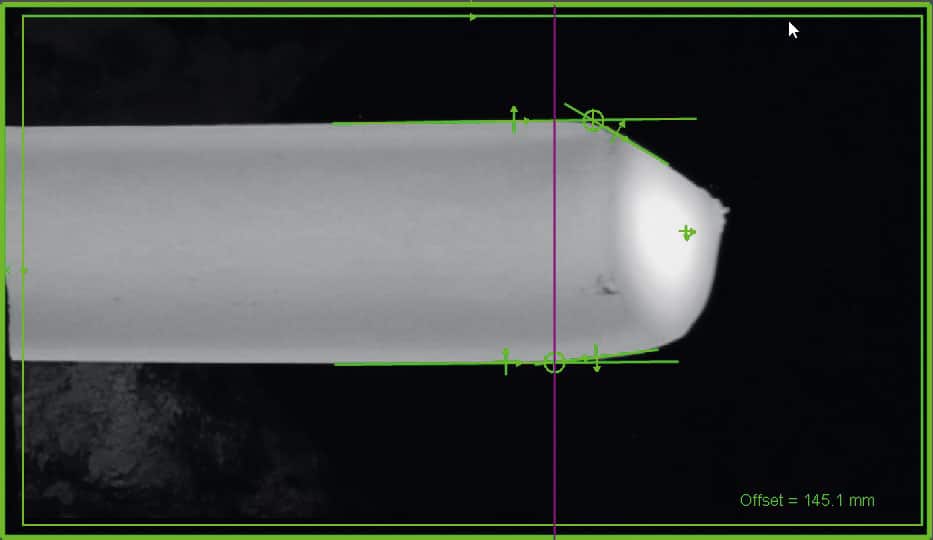

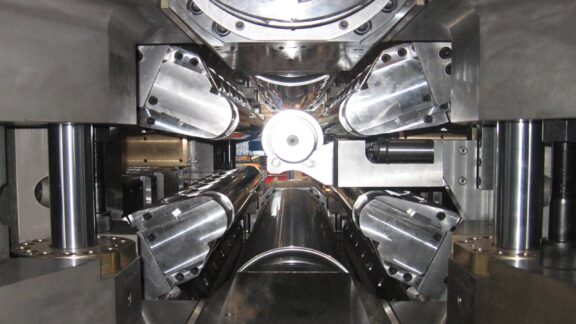

For long rolling, Primetals Technologies offers a portfolio of sensors capable of measuring and supporting process improvement. To name just a few: vision systems and non-contact laser gauges used to measure product height, length, and speed, which are all measurements previously unavailable from the roughing and intermediate mills; and RFID technology for product tracking and logistics control.

Vision systems can monitor “what the eye can’t see,” as these cameras can be positioned in mill areas that would be unsafe for operators. They relay continuous images for real-time analysis and dynamic control of the process. Installing the cameras in hazardous areas increases the safety of the operation, in particular for mill personnel.

Laser gauges measure “true product speed.” Having this information along the mill line not only enhances the mill-control system and mill setup but also increases the cut-length accuracy of shears.

When vision systems are combined with non-contact laser gauges, the mill-control system can dynamically monitor product height and width throughout the mill line. Laser gauges track product speed from the furnace exit through to the finishing end. These systems alone lead to a consistent mill setup with dynamic control, which improves yield, product tolerance, and quality. It also increases the flexibility of the operation, and reduces operating costs.

A selection of Smart Sensors developed for long-rolling applications

Process expert system

Data from new sensors is only useful when it can be analyzed to adapt mill processes. Meeting today’s demands for flexible and economic production of long products requires production process, electrical, and automation solutions that are based on precise process modeling, high-performance control systems, and an in-depth understanding of long-rolling technology. These tools for long-rolling mills can all be considered part of Industry 4.0 packages.

Process Expert is a result of close cooperation between long-product manufacturers and Primetals Technologies engineers. The system enables continual improvement by examining a plant’s manufacturing operations as one system, rather than many small systems contributing to a single operation. Mill owners shared what was missing in their existing process-automation systems. Primetals Technologies engineers met with specialists in basic automation, process automation, and technological and process management to develop a system to represent that missing link.

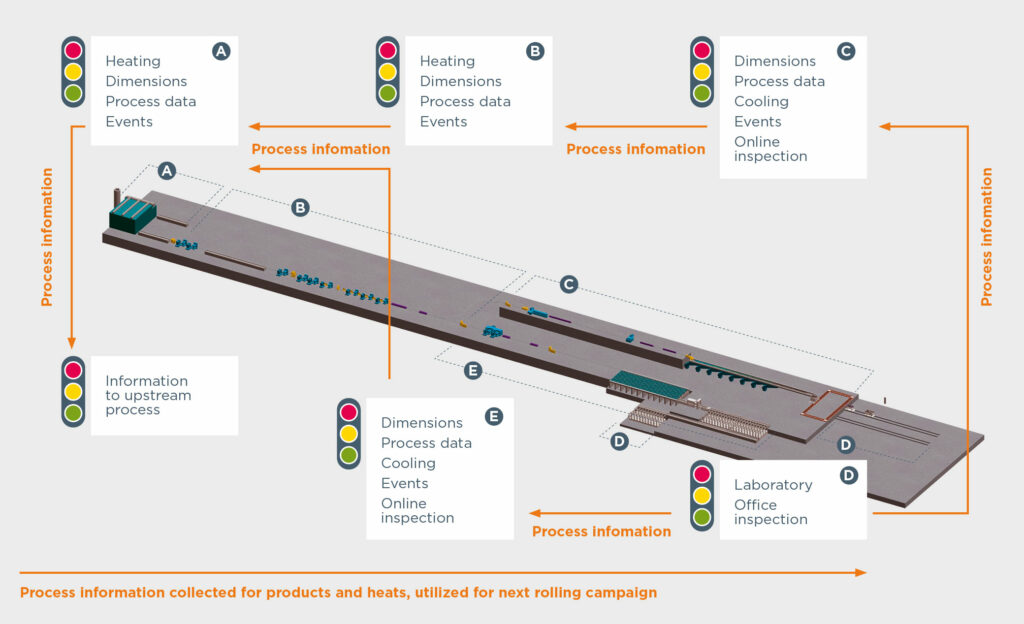

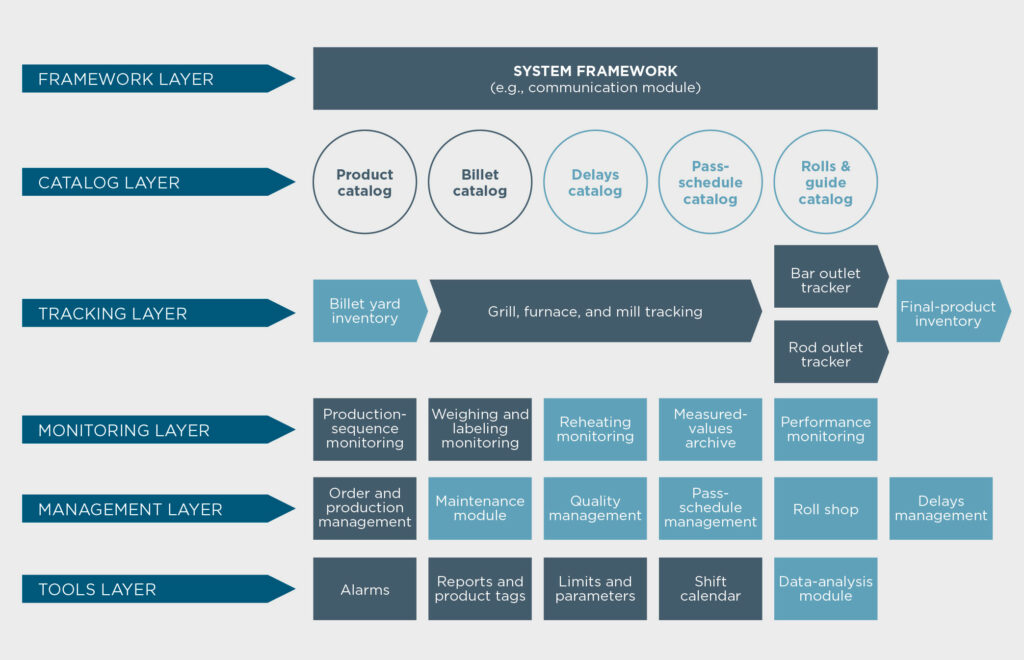

Through a communication module, Process Expert monitors and collects data from the raw-material stage through to the finished product. Its domain extends from the enterprise-resource planning, through manufacturing-execution systems, to control systems down to Level 1 devices. Tracking usually covers areas such as grill, furnace, and mill, and then—depending on the line configuration—bar outlet or rod outlet. A final module weighs and labels the mill’s end product, but outside of the plant, the system can also support billet and product-yard inventory. The system delivers mill reports to operator staff and facility managers, enabling them to assess a plant’s performance and optimize production. Not limited to one plant, this system supports plant-to-plant performance evaluation at the corporate level.

Condition monitoring

How is your mill feeling? When a long-rolling mill is running well, plant managers want the assurance that it will roll just as well in weeks to come. Suppliers can guarantee recognition of all elements contributing to plant operation, particularly when applying mechanical and electrical knowledge of the equipment and the process to monitor the condition of the entire plant— not just the rolling-mill equipment but also upstream and downstream components. Used to establish a predictive-maintenance schedule, this data ensures that any downtime or shutdowns are scheduled for maximum efficiency, thereby alleviating pressures on the maintenance staff.

As part of the Industry 4.0 shift toward data gathering, a rolling mill’s process is constantly assessed and logged to ensure that its process is within acceptable limits. If it falls out of the limits, the control system will use this information and feed it into the control algorithm to bring the process back into limits.

Equipment-condition data is acquired at each plant level, then processed and evaluated against known operating standards, and finally reported back at the plant level. Utilizing the equipment knowledge among suppliers, the system can process the data and issue alerts whenever maintenance is required. Knowing the status of the equipment throughout the full process line helps to maintain quality as well as improve plant productivity.

The system automatically produces work instructions for maintenance personnel (including any spares required), together with any additional information necessary for execution of the respective maintenance project. It may supply data obtained through 3D interactive models on tablets, which further minimizes downtime.

Cyber-physical systems

Another element of the Industry 4.0 portfolio for long rolling mills is cyber-physical systems. Used to verify the consequences of changing the plant conditions, cyber-physical systems are based on virtual models—a digital representation (“digital twin”) of the real physical plant or process, formed from integrations of computation, networking, and physical processes. Embedded computers and networks monitor and control the physical processes with feedback loops, illustrating where physical processes affect computations and vice versa.

Long-rolling producers require flexibility and high efficiency in their production cycle. Advancements in software and powerful network systems provide the tools to collect, sort, and analyze large amounts of data. When used within cyber-physical systems, these tools enable offline production simulation with the ability to monitor, analyze, and measure against designated key performance indicators to evaluate whether the planned production will meet higher standards.

Representing the future of process automation, cyber-physical systems can model an individual process, such as a cooling module, to calculate the temperature equalization in a rail mill, the water-box setup in a conventional rod or bar mill, or a mill setup and roll-pass calculations. Utilizing cyber-physical systems in the future, mill operators and supervisors will be able to understand the effects of a change in setup of a certain process or piece of equipment before the change is made, and make those changes with confidence. On a broader scale, the use of cyber-physical systems will be a critical factor in optimizing the entire value chain, evaluating new business models, and integrating new business partners.

Through-Process Optimization

Already in use in long-rolling mills, this additional Industry 4.0 package, Through-Process Optimization (TPO), helps mill operators achieve intended product specifications, and supports quality management. It accomplishes this through the identification of non-conformities, determination of the related root cause, and provision of corrective and compensational actions throughout the entire steel-production chain.

This system integrates the quality know-how of a product with the real-time production process. A rule-based system checks the resulting data at each process event. Based on these rubrics, it decides whether product quality is within the defined limits. The system then determines corrective dynamic adjustments to both upstream and downstream processes. This consequently enhances overall product quality by both preventing further quality issues from occurring and rectifying those detected.

Production- and maintenance-management systems

Production- and maintenance-management systems for long-rolling mills provide yet another source of data for the Industry 4.0 portfolio. To ensure production facilities are fully utilized, a Production-Management System can dynamically plan and track a facility’s production to optimize each step in the process—from the first product order to final delivery. Armed with this data, a plant manager can respond to customer requests with greater flexibility and run a leaner operation.

For ongoing plant maintenance, a computerized maintenance-management system works in parallel with the Production-Management System to manage and execute maintenance activities by flagging tasks and other scheduled action items for greater efficiency. The system incorporates built-in knowledge of a facility’s overall maintenance strategy and production system, and maps that against data points supplied by onsite sensors.

Revolution or evolution?

Is Industry 4.0 a revolution or evolution of technology for the long-rolling industry? From a technical point of view, it is an evolution that needs to be implemented not just in long rolling but across the metals industry as a whole. Once the analytical drivers of Industry 4.0 merge with the production process, it will turn into a revolution. In many ways, Industry 4.0 is no longer a vision of a distant future, as much of it has already arrived. Elements of this approach are already being developed, installed, and tested globally. By implementing the measures outlined in this article, long rolling mill owners can, utilizing the expertise of suppliers, manage the digital transformation of their production plants. They can establish both their short- and long-term goals in a phased approach, optimize the implementation of these ever-evolving technologies, and harness the full power of Industry 4.0.

Where does all this lead? Some say that it will promote the development of a fully automated factory. Solutions are now available to make possible the digitalization of an entire long-rolling mill, from the liquid phase all the way through to the finished product. Steel producers who plan to implement these new technologies in the near future will find great support in the counsel and collaboration with expert partners—such as Primetals Technologies’ engineers.