Few artificial intelligence solutions have stood in the limelight quite like ChatGPT by developer OpenAI. Entire industries are fearing the disruption the technology may bring. Others look forward to a world in which many arduous, time-consuming processes will be automated or directed to the AI for execution. But how much does ChatGPT know about the metals business? Does it have the insight required to support steel producers in achieving long-term sustainability? We asked the AI to discuss the ten most important factors for producers wanting to become greener. Our series continues with a focus on energy efficiency, renewable energy, and recycling.

2. Energy Efficiency

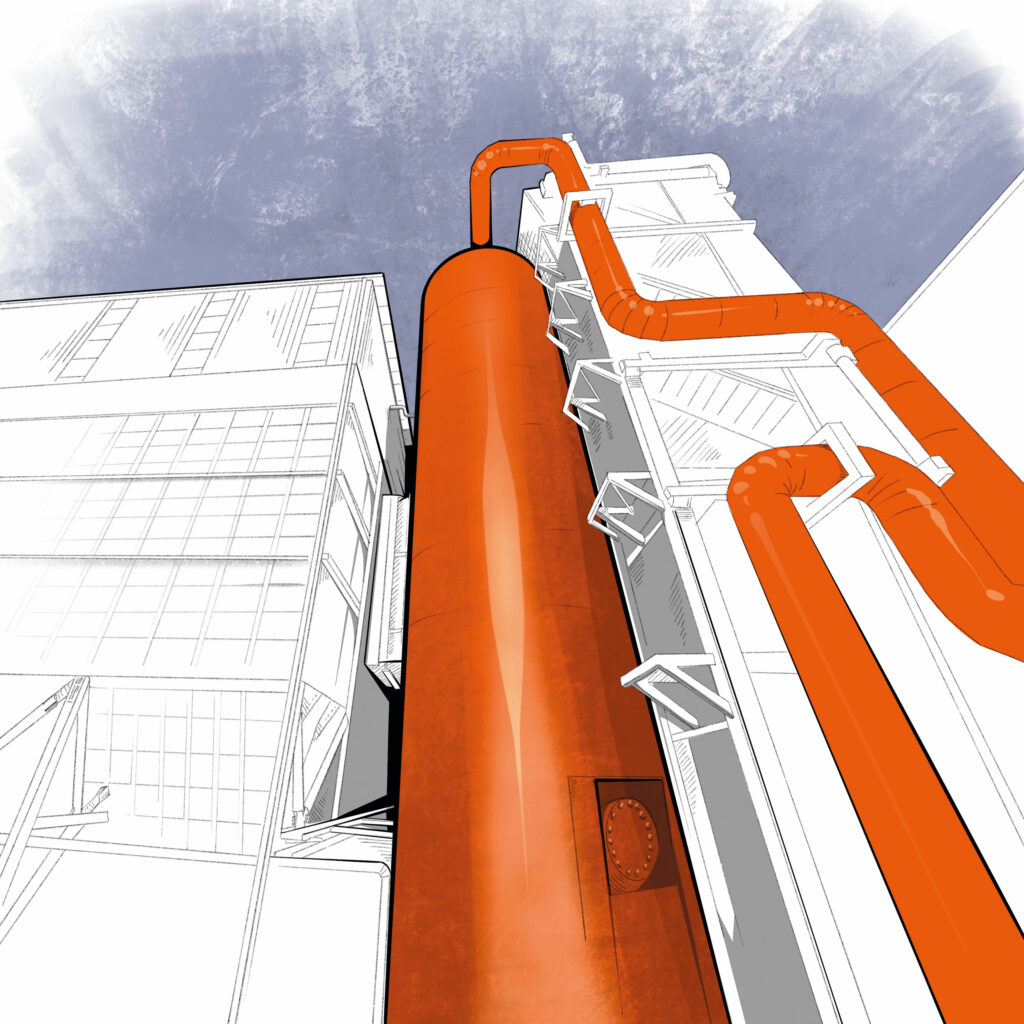

“Improving energy efficiency is a critical factor in making steel production more environmentally compatible and sustainable. As the industry faces increasing pressure to reduce its carbon footprint, steel producers must prioritize energy efficiency to stay ahead of the curve and remain competitive in the long term. One way to improve energy efficiency is by upgrading equipment and technologies used in the production process. Traditional blast furnaces are highly energy-intensive, consuming large amounts of coke, coal, and other fossil fuels. Electric arc furnaces, on the other hand, use scrap metal as raw material and are more energy-efficient. By investing in advanced technologies such as electric arc furnaces and improving the energy efficiency of existing equipment, steel producers can significantly reduce energy consumption and greenhouse gas emissions. Another approach to improving energy efficiency is to optimize processes by reducing energy losses and improving process control. Advanced control systems can optimize process parameters and reduce energy consumption by adjusting the flow rate of materials, optimizing temperature levels, and controlling the use of energy-intensive equipment. Regular maintenance and tuning of equipment and systems can also optimize energy use and improve energy efficiency.

Steel producers can also consider adopting renewable energy sources such as wind, solar, and hydro power to reduce their reliance on fossil fuels. By investing in on-site renewable energy production or sourcing renewable energy from external suppliers, producers can significantly reduce greenhouse gas emissions and improve the environmental performance of the steel industry. Moreover, energy-efficient operations can be achieved by optimizing the management of energy use. This includes conducting regular energy audits, setting energy performance targets, and implementing energy management systems. By continually monitoring and assessing energy performance, steel producers can identify opportunities for improvement and take appropriate measures to reduce energy consumption and greenhouse gas emissions. This can also help steel producers to reduce their energy costs and improve the economic competitiveness of the industry.”

3. Use of Renewable Energy

“The use of renewable energy is another critical factor in making steel production more environmentally compatible. Steel production is one of the most energy-intensive industries in the world, and reducing the industry’s reliance on fossil fuels is essential in mitigating its environmental impact. Steel producers can significantly reduce their greenhouse gas emissions by using renewable energy sources such as solar, wind, and hydroelectric power. To take advantage of the opportunities offered by renewable energy, steel producers must invest in the respective infrastructure and technology. This includes installing solar panels, wind turbines, and hydroelectric generators at their facilities, as well as partnering with renewable energy providers to purchase renewable energy credits or enter into power purchase agreements. By investing in renewable energy infrastructure and technology, steel producers can reduce their greenhouse gas emissions and improve their environmental performance.

Additionally, the use of renewable energy can offer economic benefits to steel producers, such as reduced energy costs and increased energy security. As the cost of renewable energy continues to decrease, renewable energy can also provide a competitive advantage to steel producers, enabling them to differentiate themselves from their competitors and attract environmentally conscious customers.

An example of a company taking advantage of the opportunities offered by renewable energy is ArcelorMittal Europe. The company has set a target of reducing its carbon footprint by 30 percent by 2030 compared to 2018 levels, and expects to be carbon neutral by 2050. It has industrial-scale demonstration projects under construction for every part of its carbon-neutral roadmap, and it is building industrial-scale demonstration plants at its operations in Belgium and France.

In addition to investing in renewable energy infrastructure and technology, steel producers must also focus on improving the energy efficiency of their operations. This includes optimizing their production processes, reducing waste, and using energy-efficient equipment and technologies.”

4. Recycling

“To remain relevant in a rapidly changing world, steel producers must embrace innovative technologies that allow them to produce high-quality steel products while minimizing their environmental impact. One innovative technology that has gained popularity in recent years is electric arc furnace (EAF) steelmaking. EAF steelmaking uses scrap metal as the primary raw material instead of iron ore, reducing the carbon footprint of the steel production process. Steel producers who invest in EAF technology are not only reducing their environmental impact but also gaining a competitive advantage over traditional blast furnace steelmakers. Another innovative technology that has the potential to transform the steel industry is hydrogen-based steel production. This technology uses hydrogen instead of coal or coke as a reducing agent, eliminating the carbon emissions associated with traditional steel production methods. The use of hydrogen also creates water as a by-product, which can be recycled in the production process. While hydrogen-based steel production is still in the early stages of development, several steel producers have already announced plans to invest in this technology in the coming years. Steel producers can also look to innovative technologies outside of the production process itself. For example, artificial intelligence (AI) and machine learning can be used to optimize production processes, reducing waste, and lowering energy consumption.

The benefits of embracing innovative technologies are numerous. First and foremost, investing in innovative technologies can help steel producers reduce their environmental impact and increase their sustainability. This is becoming increasingly important to customers, investors, and governments alike. Second, embracing innovative technologies can help steel producers stay ahead of the competition. By using new technologies to create products that are more environmentally friendly, more efficient, and of higher quality, steel producers can differentiate themselves from their competitors and attract new customers. Finally, embracing innovative technologies can also help steel producers reduce costs and increase profitability. And by producing steel products that are more environmentally friendly, steel producers can take advantage of government incentives and regulations that reward sustainable practices.”

To ensure that your interactions with ChatGPT are as effective as possible, it’s important to keep a few key considerations in mind. Here are some tips to help you get the best results.

- Be specific in your questions: ChatGPT works best when given clear and specific questions or prompts. This will help it generate more accurate and helpful responses.

- Use correct spelling and grammar: ChatGPT relies on natural language processing, so it is important to use correct spelling and grammar when interacting with it. This will help ensure that it understands your queries and generates appropriate responses.

- Provide context when necessary: If you are asking a complex question or providing information that may be relevant to your query, be sure to provide context to help ChatGPT better understand your request.

- Be patient: ChatGPT is a sophisticated AI model, but it may take some time to generate a response, particularly for complex queries. Give it time to process your request.

- Use it as a tool, not a replacement for human interaction: While ChatGPT can be a helpful tool for answering questions and generating text, it is important to remember that it is not a replacement for human interaction.