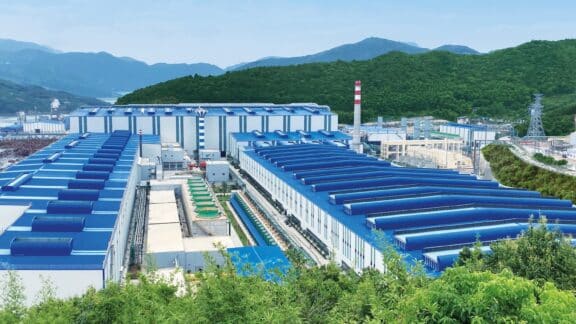

ESP line No. 2 at a Chinese steel producer in Hebei province, China, is now in operation, making it the 9th ESP line worldwide. The customer’s first ESP line has been in operation since 2021. With a speedy startup, the first hot-rolled coil was produced in endless mode just nine weeks after the beginning of cold commissioning, and the first coil of 0.8-millimeter thickness was produced just 50 days later.

This new ESP line expands the production capacity of high-grade strip and cold-rolled substitutes, building on the market success of the coils produced by line Nr. 1. Primetals Technologies was responsible for engineering and supplying the complete process equipment and the automation system.

Meeting High-Quality Demands

Thanks to the new line’s endless casting and rolling process, the Chinese steel producer will manufacture hot-rolled products of high quality with uniform mechanical and geometrical parameters from the strip head to the tail, at widths of up to 1,600 millimeters and thicknesses down to 0.7 millimeters. The product mix includes carbon steels, high-strength, low-alloyed (HSLA), and soft steel. The steel producer targets the market for substitute material of cold-rolled coils, made possible by the superior surface quality and consistency of hot-rolled coils produced in endless mode. These coils already obtain a controlled microstructure at the hot-rolling stage—a structure that meets the requirements of high-quality cold-rolled material applications, such as deep drawing sheets.

Extensively Compact Casting and Rolling

Compared to other ESP lines, the defining feature of this innovative ESP line is the process and layout optimization focused on ferritic, i.e., low-temperature rolling. Low-temperature rolling is realized with a dedicated Power Cooling unit ahead of the finishing mill and a concise cooling line, resulting in an unprecedented length of about 150 meters for the entire plant, measured from the caster turret to the first downcoiler.

Arvedi ESP Means Green Steel

On top of its unparalleled productivity and performance, as well as its capability to produce high-end strip, Arvedi ESP is the only officially certified carbon-neutral thin-slab casting and rolling process. This fact was confirmed in 2022 by third-party certificates received by leading Italian steel producer Acciaieria Arvedi, who operates the ESP master plant.

The defining feature of its layout is the absence of a fossil-fuel-fired tunnel furnace for reheating the slabs before rolling. Thanks to the high-speed casting process, the thermal energy of the cast slab allows for direct rolling without adding a significant amount of energy. Any necessary temperature adjustment, i.e., fine-tuning the finishing temperature, is made using a very compact inductive heater just before the finishing mill entry.

Compared to conventional casting and rolling processes, the ESP line’s energy consumption and related costs are reduced by 50 percent, while its direct CO2 emissions from production are reduced.

MORE INFORMATION

Click here to read the full press release, access contact details, and find other press resources.