Hyundai Steel has recently implemented Eco Slide Discs from Primetals Technologies at its steel plant in the city of Dangjin, in the Western part of South Korea. After installing Eco Slide Discs at the hot strip mill’s down coiler No.1, Hyundai Steel implemented Eco Slide Discs for down coiler No. 2.

Established in 1953, Hyundai Steel produces hot-rolled steel sheet, thick plate, cold-rolled steel sheet, galvanized steel sheet, and rebar for several industries, including the automotive sector. Hyundai Steel plans to strengthen its competitiveness further with special steel products and abrasion-resistant materials for automotive engines and transmissions.

Maintenance Advantage

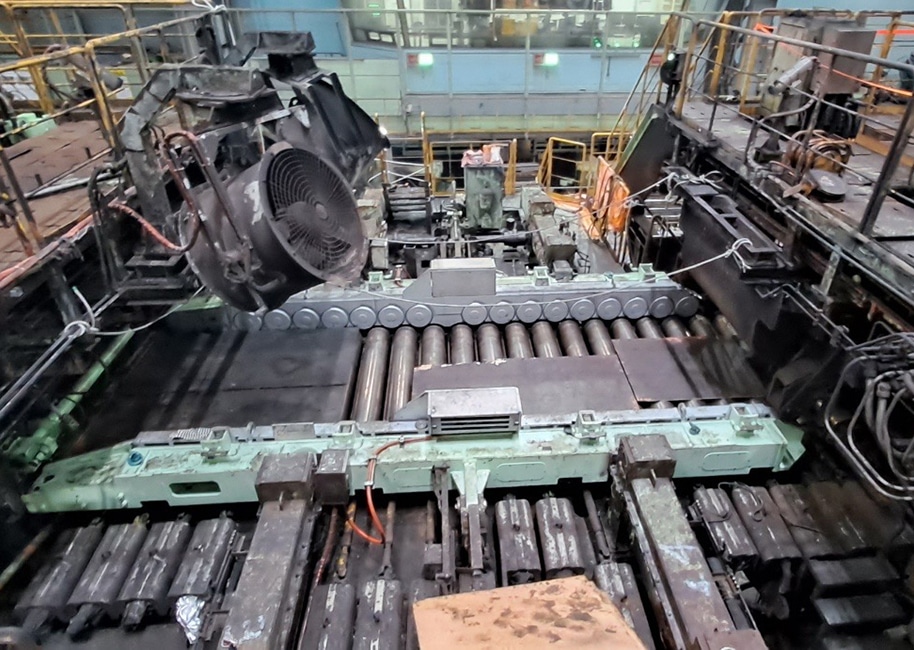

Two Eco Slide Discs from Primetals Technologies, including rotating discs, disc drives, and two guiding beams, were implemented at Hyundai Steel, improving maintenance intervals from six weeks to several months. This dramatic improvement has significantly reduced maintenance-related expenditures, turning maintenance performance into an advantage.

Away from Convention for Improved Quality

Eco Slide Discs move away from conventional designs so that wear is evenly distributed around the entire disc surface, extending the entire side guides’ lifetime and period of continuous operation.

The strip guiding beams also have a self-cleaning effect that prevents strip-surface defects from occurring, as these usually result from burning burrs falling off the conventional wear plates. In addition, the periodic rotation of the discs eliminates the need for manual cleaning to prevent strip-edge deposits. Finally, because of the evenly distributed wear of the discs, strip-edge defects and the risk of strip cobbles prompted by worn-out guiding grooves are avoided.

Steel plant operators no longer have to execute time-consuming inspections, welding, and grinding repair work with the new discs, eliminating inline activities and improving operator safety.

MORE INFORMATION

Click here to read the full press release, access contact details, and find other press resources.