While carbon emissions have received a great deal of attention as heavy industry moves toward eco-friendly production processes, the definition of how to divide up the emissions generated by businesses have led to the creation of “scope emissions.” Learn how these emissions impact steel producers and how these regulations will impact a sustainable steel industry.

Carbon emissions and other greenhouse gas emissions (GHG) have long been a concern for heavy industry as pressure to cut back on pollutants and emissions has led to a warming planet that has increased immensely over the past two decades. To define and establish responsibility regarding emissions, global organizations have established definitions and systems for emitters worldwide. Among these definitions and systems are emissions trading systems, such as the European Union’s emissions trading system and the GHG protocol definition of scope emissions.

The Need for Scope

What has become a delicate issue for heavy industry is the reality of carbon emissions and their impact on the environment. Pressures to improve production efficiency and reduce waste, including pollutants, have drawn many in heavy industry to look toward advancing their production capacities toward eco-friendly technologies. Moreover, this has also led to an increased focus on recyclability. However, industry emitters and policymakers found the subject of carbon emissions tricky to define.

For example, suppose an emitter from a “hard-to-abate industry,” such as the steel industry, is meant to take responsibility for the carbon emitted during production. In that case, the question arises about what falls under that category. Oversimplified, some might suggest that producers are responsible for all emissions—full stop. However, this would mean that the producer is responsible for the carbon emitted while procuring raw materials for liquid steel production and the emissions from transporting said material. Once production begins, then the emissions from the reduction of iron ore to the production of liquid steel until a finished product. However, would the responsibility end with the finished product or upon delivery to the end user? What do we make of emitters across the value chain? Moreover, how should companies handle energy consumption and the emissions from energy production? All these questions have been answered with “scope.”

Understanding Scope Emissions

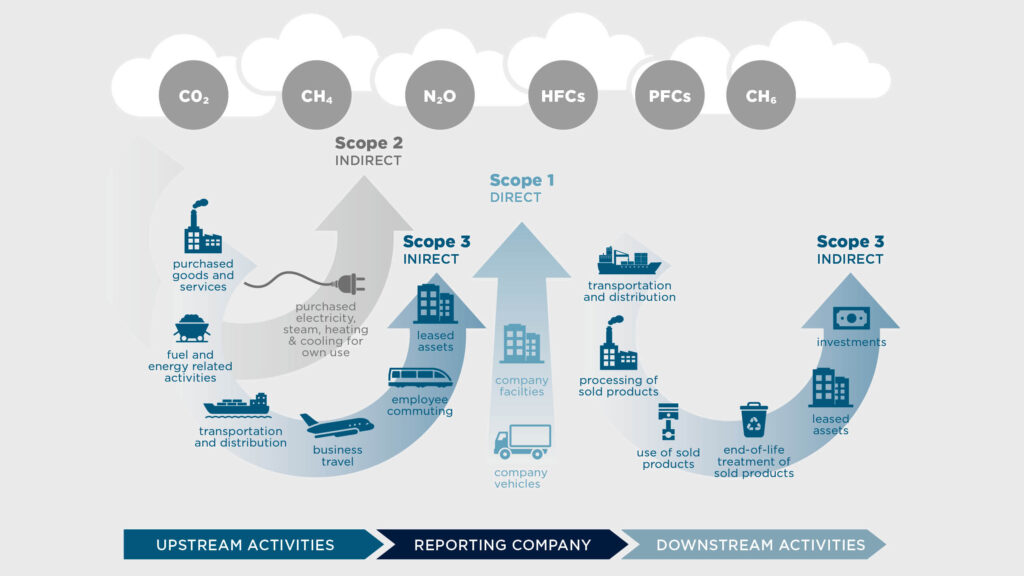

Scope emissions, namely, Scope 1, 2, and 3, define and set boundaries for producers’ responsibility for emissions as set by the greenhouse gas protocol. Scope emissions effectively clear up any confusion regarding the assignment of responsibility regarding carbon emissions into three simple categories.

Scope 1 emissions are those produced directly from sources that a company owns or controls directly. For a steel producer, these sources would include CO2 emitted during the steelmaking process, such as emissions from a direct reduction plant, meltshop, or rolling facility. When looking to reduce the amount of carbon emissions from their plant, then the difference between a direct reduction plant and a blast furnace for steelmaking, the difference in Scope 1 emissions is clear.

Scope 2 emissions make things more complex as they include the emissions from electrical energy generation. For a producer, this would include the energy associated with operating an entire plant, which is particularly relevant for electric steelmaking, as electric arc furnaces place a significant demand on the grid and consume high amounts of electricity. Depending on how the energy— e.g., via nuclear or hydroelectric power—is produced would then determine the amount of additional emissions categorized as Scope 2.

Scope 3 emissions are all remaining emissions through the value chain. This definition has remained the most ambiguous and will likely see its impact in specific carbon emissions trading systems or carbon taxes as it may relate to specific industries more than others. For a producer, this may or may not include the shipment of end products to customers, carbon emissions from transporting raw materials, or even the amount of carbon emissions generated by suppliers.

Scope Emissions and the Steel Industry

While the definition of scope emissions does not directly impact the law, the impact of regulations regarding carbon emissions will increase over the coming years. With ambitions and targets set around the world regarding carbon neutrality, the ability to define, regulate, and control greenhouse gas emissions will play a crucial role in funding environmentally friendly projects and adopting eco-friendly technologies. For the steel industry, scope emissions—particularly Scope 1 and 2—will play a vital role in considering production routes as the industry shifts away from the conventional blast furnace-basic oxygen furnace route toward increased use of direct reduced iron and scrap-based and electric steelmaking.

The industry is already shifting toward eco-friendly production routes, including direct reduction and electric steelmaking. In 2022, tons of CO2 per ton of crude steel remained stable, while energy intensity decreased from levels in 2021. Furthermore, newly established cooperations between producers and adjacent industries, such as raw material suppliers and energy companies, are emerging as these “hard-to-abate” sectors see value in working collectively to reduce emissions. As the industry transitions worldwide, energy intensity and impact of carbon emissions will see a reduction to meet carbon-neutral targets.

DETERMINE YOUR CARBON EMISSIONS

The CO2 Calculator from Primetals Technologies is designed to appoximate the carbon footprint of a steel plant. Click here to learn more.