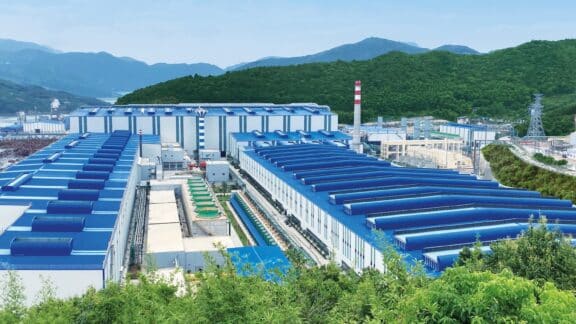

In April 2024, a much-anticipated signing ceremony was held in Vienna, Austria. The event marked China’s Zhongshou Special Steel Group’s strategic decision to invest in the groundbreaking Arvedi ESP technology, following a diverse group of forward-looking steel producers in North America, Europe, the Middle East, and China. Zhongshou’s Arvedi ESP plant will offer the same tried-and-tested benefits as the ones previously implemented and represents the 12th Arvedi ESP production line to become operational globally. Startup is expected for the end of 2025.

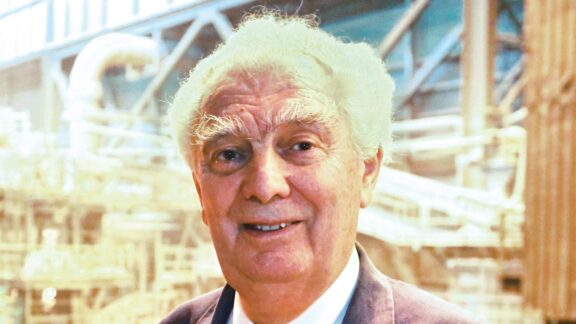

Zheng Ting Wen, Chairman at Zhongshou Special Steel Group, outlines his main reasons for choosing Arvedi ESP technology:

“I want to benefit from maximum product and operational flexibility to optimally serve our customers, with the best quality and the lowest impact on the environment,” he says. “Thanks to the proven and consolidated application of the endless process, this is the most advanced technology currently available on the market. Because of the numerous and successful applications presently operating in China, we have been convinced of its superiority.”

Chairman Zheng adds: “During the discussions with Primetals Technologies, our team made clear our goal to run the most powerful and most flexible ESP solution developed to date, fully benefitting from the experience gained from the already existing plants: this is the reason why we have selected an ESP configuration with a thicker slab—up to 135 millimeters—and a 4-stand high-reduction mill configuration, unprecedented in China.” Zheng’s statement is a testament to his company’s visionary approach that informed the strategic development process with Primetals Technologies.

Unprecedented Product Range

This plant has been conceived to target the unprecedented range of strip thicknesses between 0.7 and 12.7 millimeters—all in full endless operation. It will cover an extremely extensive mix of steel grades as endless hot-rolled coil (eHRC), ranging from carbon grades for commodity applications, such as cold-rolled substitute in thin and ultra-thin gauges, to sophisticated AHSS at higher thicknesses, suitable for applications in the energy and automotive sector.

Franz Hermann Glaser, Sales Director for Arvedi ESP at Primetals Technologies, points out two standout features of the new plant: “This facility can be labeled ‘zero greenhouse direct emissions,’ as both the casting and rolling will operate completely without consuming any natural gas. Its ultra-low power requirements are unparalleled, thanks to the direct, energy-saving connection between the caster and the rolling section.”

Glaser is convinced that Zhongshou’s ESP plant will empower the company to enter even the most challenging markets: “The plant will enable Zhongshou to serve not only its domestic market with the greenest steel products but also to expand its presence on the international market. Zhongshou’s products will be compliant with the most stringent carbon border adjustment regulations, which are already playing a role when exporting to certain countries.”

Transformational Technology

The festive event highlighted not only the strategic benefits that producers can expect from choosing Arvedi ESP but also the technology’s central role in the transformation of the steel industry. As an ultra-compact production line that includes every aspect from thin slab casting to rolling of flat steel, the solution offers decisive advantages along multiple dimensions: economic, technological, and environmental.

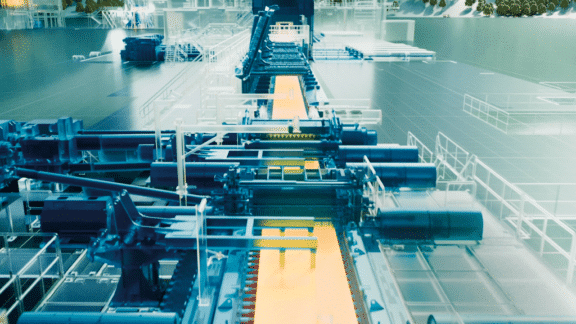

Christoph Fellner, Vice President of Endless Strip Production at Primetals Technologies, outlines some of the key reasons why producers prefer ESP over other available technologies: “In essence, Arvedi ESP offers the highest product quality, lowest operating costs, fastest ramp-up curves, and lowest full-turnkey investment costs on the market. Our customers often tell me that, after extensive research, they discover that ESP is the only solution available that enables real endless operation. While other production lines make use of tunnel furnaces to compensate for their technological shortcomings, Arvedi ESP’s patented design realizes a direct connection between the casting and rolling sections. This technological superiority enables producers to enter high-profit markets: they can sell the endless hot-rolled coil (eHRC)—which has already established itself as a new and highly desirable product category in many of the world’s regions.”

Jürgen Scholler, who heads the ESP Process & Technology department of Primetals Technologies, discusses some of the key features of Arvedi ESP that contribute to the solution’s overall success: “The direct coupling of the high-speed caster and the rolling mill makes use of the energy inherent in the strand to lower the roll forces in the high-reduction mill. As a result, it achieves ultra-high reduction levels while the bite angle is rendered less significant. The production line’s compact, 180-meter, size lends itself to implementations even on brownfield sites that are facing space constraints.”

Full Plant Digitalization

Arvedi ESP’s endless operation rests not only on the sophistication of its components but also on the advanced nature of its automation system. Because ESP unites a large number of production steps, a holistic approach to automation was required. Everything from the solidification of the liquid steel to the plastic deformation and phase transformation at the rolling stage is carefully synchronized on the basis of sophisticated models. The result is one single, unified automation system, perfectly tailored to the requirements of Arvedi ESP’s endless process.

The coordinator of the electrics and automation efforts for ESP, Emmanouil Apostolatos, is proud of his team’s achievements: “We integrated all models and controls into one comprehensive system to meet the requirements of running an endless process and to ensure high-end steel production,” he says. “At the heart of our approach is the idea to realize full plant digitalization—by use of artificial intelligence driven physical models, advanced ‘Industry 4.0’ technology packages, and our innovative Central Operation Cockpit, combined with our digital assistants.”

Apostolatos adds that advanced motors and drives, directly supplied by Primetals Technologies, contribute to Arvedi ESP’s super-stable operation and high performance. He is proud of the breakthroughs made automation-wise with earlier ESP plants: “Zhongshou’s Arvedi ESP line will profit from the advances we made on our 11 previous implementations, all of which feature our best-in-class automation solutions. Results from these plants show that our automation system addresses the critical needs of operators, engineers, and managers. It is also continually improved to meet any future requirements.”

A Perfect Match for China

Arvedi ESP has attracted steel producers from many of the world’s regions, but China has become one of the markets where the technology has gathered particular interest—in spite of the transformation that is unfolding in the country’s steel sector. Tomislav Koledic, CEO of Primetals Technologies China, explains why Arvedi ESP is an ideal match for Chinese producers striving to successfully take their business into the coming decades: “China is currently entering a new phase of development characterized by lower demand for steel and greater competition. Consequently, our customers are looking for the technologies that will provide them with a clear competitive advantage.”

From his conversations with Chinese producers, Koledic has learnt that many of them focus on four key aspects: “They want production equipment that offers higher energy efficiency, improved production flexibility and product quality, as well as a reduced carbon footprint. Arvedi ESP delivers on all these crucial fronts, and, as the large install base in China indicates, it remains the top choice for our Chinese customers.”

To date, Arvedi ESP technology has produced more than 110 million tons of endless hot-rolled coil (eHRC). The scope of products made with ESP includes ultra-thin steels never before manufactured in larger quanties using any kind of casting and hot-rolling technology. Arvedi ESP has therefore become—and will remain—the industry standard for the production of endless hot-rolled coil (eHRC). It has taken the clear leadership role in terms of technological advancement, product quality, profitability, and environmental compatibility. This leadership role will only become more prominent in the future—as the Arvedi ESP install base continues to grow.

LEARN MORE

Click here to find out more about Arvedi ESP – Endless Strip Production.