High-end maintenance concepts and technologies have recently gained more attention, partly because of the challenges facing steel producers on account of global overcapacity. BOX Concept, the highly advanced condition-monitoring solution of Primetals Technologies, was designed to minimize the risk of unplanned shutdowns, maximize plant availability, and ensure product quality and worker safety.

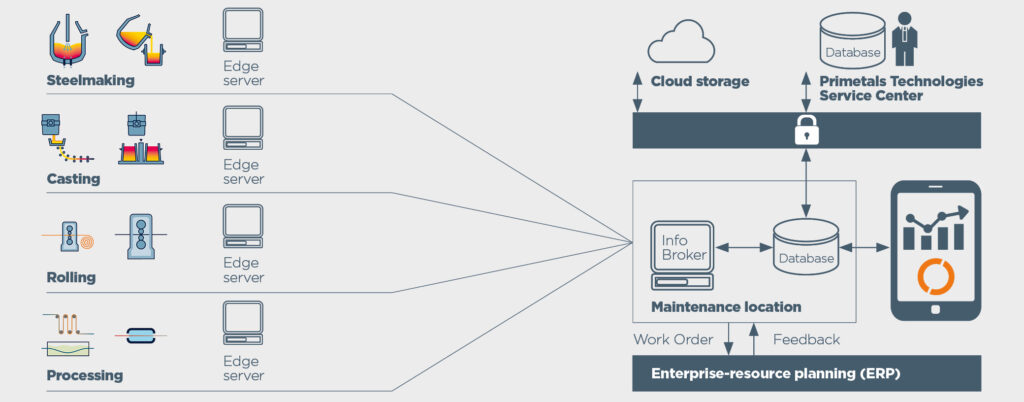

BOX Concept uses an architecture that is based on an Edge computing system. While other solutions typically require three separate system suppliers (one for data acquisition, one for data processing, and one for analysis and evaluation), the BOX Concept from Primetals Technologies comprises all three. The field-measurement data is acquired by special measuring devices, while other process data (e.g., related to material tracking) is obtained directly from programmable logic controllers through proprietary software interfaces. Core evaluation and data compression are executed on several Edge servers in one or more plants. The results are then sent via a machine-to-machine interface to a central, web-based information-management system called the “Info Broker,” which encompasses a database.

- Early fault detection reduces repairs and costs

- Extended equipment lifecycle

- Lower maintenance expenditures

- Increased plant availability

- Optimized and more reliable production management

- More consistent end-product quality

- Highest safety levels for human operators

- Promotes technological leadership

Web-based architecture

Thanks to the web-based architecture of the BOX Concept, plant managers can easily access the information or reports they desire using a smartphone or a tablet, either via an authorized connection to the plant network or by scanning a dedicated QR code on the respective piece of equipment. Additionally, datasets and evaluations can be uploaded to a cloud-storage solution for further utilization—such as investigations based on machine learning. Information can also be transmitted to the Primetals Technologies Service Center through a secure gateway for extensive analysis and customized reporting. Unlike more conventional condition-monitoring systems, the BOX Concept facilitates interfacing with superordinate functions such as enterprise-resource planning (ERP). The BOX Concept solution enables the maintenance staff to systematically generate work orders and send them to the ERP. A feedback loop back from the ERP to the BOX Concept for all work orders is also provided. Existing condition-monitoring systems and stand-alone measurement systems can be integrated into the BOX Concept.

The CMS of choice

Overall, the BOX Concept is the platform of choice for high-end maintenance operations. It is one of the key technologies for the transition to Industry 4.0 and comprises extensive metallurgical and automation-related know-how. It was designed to monitor complex equipment and processes in both the upstream and downstream areas. Lastly, it is modular, easily operable, scalable, and has a short return-on-investment (ROI).