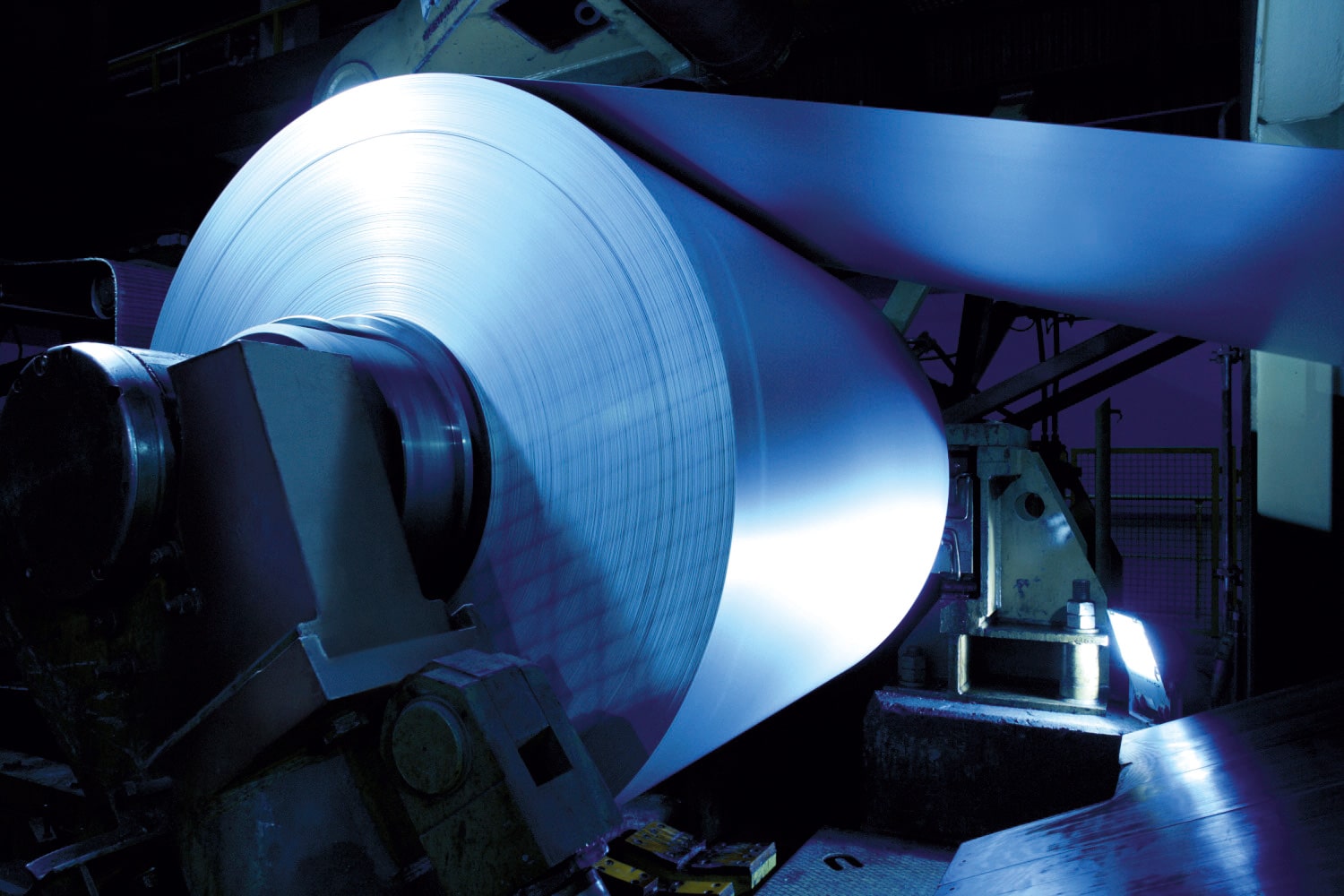

When cold strip is wound onto a mandrel, the coil is never perfectly round but slightly eccentric. These eccentricities have a number of different causes:

- A bump resulting from the strip head being wrapped on the coiler mandrel by a belt wrapper, which is propagated with each revolution

- A bump caused by the strip head coming out of the gripper slot (being used instead of a belt wrapper)

- In reversing mills, a difference in thickness emerging after a few passes between the head and tail on the one hand, and the strip body on the other

- An imbalance in the coiler mandrel mechanism

- Better strip quality

- Easy to implement in existing systems

- Fast realization of ROI

- Maintenance-friendly

This coiler eccentricity causes tension oscillations in the strip, which in turn can lead to strip-thickness errors and strip-surface defects.

Since tension disturbances are repeated with each revolution of the coiler, their frequency depends on the rotational speed. At high rolling speeds, these periodic changes are much too fast to be compensated by the closed-loop tension controller. Moreover, the behavior of the system to be controlled changes dramatically with speed, coil diameter, strip geometry, and pass reduction.

As a solution to this problem, Primetals Technologies has introduced Coil Eccentricity Compensation (CECO), which can be used for all strip types and coil diameters. It is a model-based control that makes use of the fact that the shape of the eccentricity remains relatively constant during coiling. CECO can therefore create a model of the eccentricity over several revolutions. Using an inverted plant model, the eccentricity is translated into a compensation torque for the coiler drive (pre-control).

As a result, strip quality improves: stable strip tension leads to better strip-thickness tolerances and higher strip-surface quality.