This post is also available in: 简体中文 (Chinese (Simplified))

On January 7, 2015, Mitsubishi-Hitachi Metals Machinery, Inc. (MHMM) and Siemens VAI Metals Technologies GmbH (Siemens VAI) joined forces to form a new plant-building company: Primetals Technologies Limited. On the basis of the combined technological legacies of the predecessor companies, producers can count on a strong and experienced partner to provide end-to-end excellence across the metals value chain.

The intention to establish a new joint-venture company in steel and metal production machinery was announced in May 2014 by parent companies Mitsubishi Heavy Industries, Ltd. (MHI) and Siemens AG. Equity ownership in the new venture is 51% for MHMM (an MHI-consolidated group company with equity participation by Hitachi, Ltd. and IHI Corporation) and 49% for Siemens. MHMM and Siemens VAI ideally complement one another with regard to their product portfolios, manufacturing know-how and geographical spread. The technology strengths of the former Siemens VAI lie in particular in iron and steel production, continuous casting, electrics and automation, process know-how, plant integration, environmental technologies and lifecycle services. MHMM’s competence is primarily focused on hot and cold rolling, processing and manufacturing expertise. With the combined portfolio of the joint-venture partners, Primetals Technologies offers solutions for the entire value chain in iron and steel production that extend from the treatment of raw materials up to processing and finishing of the steel products, in addition to rolling mills and equipment for nonferrous metals.

A GLOBAL NETWORK

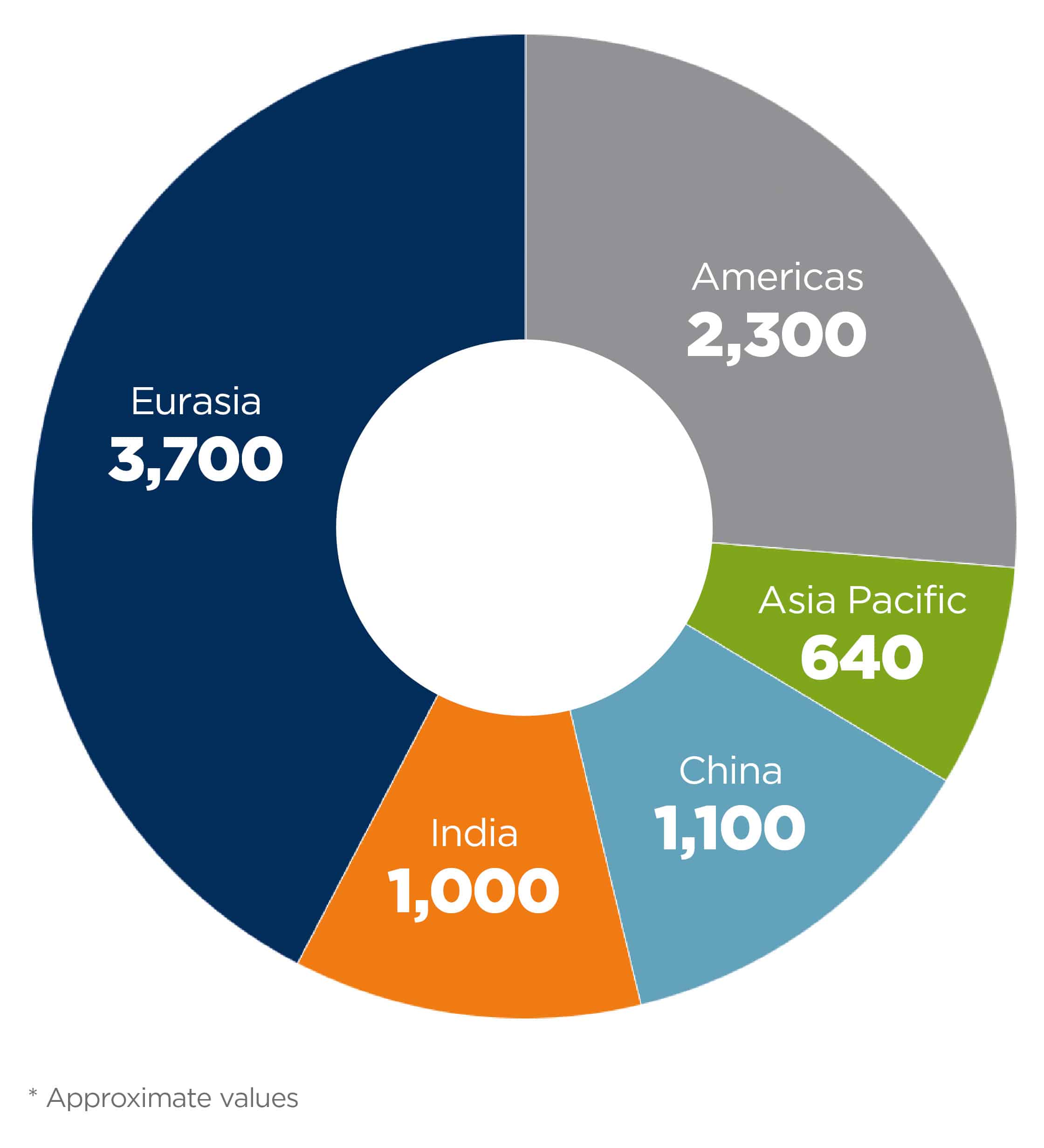

A key reason behind the merger was to establish a truly global presence. The new company has six main regional bases: Japan, Austria, Germany, the United States, China and India. MHMM and Siemens VAI are a good match with respect to geographic coverage, a factor that will enable acceleration of worldwide business expansion into Asia, Europe, Russia, the Americas and Africa. The headquarters of the new company is located in the U.K., which will manage the regional bases and maintain cross-business functions in charge of sales and marketing, customer management, procurement, manufacturing and R&D planning to support each business. Currently, close to 9,000 employees of Primetals Technologies are based in more than 40 company offices and engineering, workshop and service centers to provide immediate support to customers whenever required. In addition, the backing of the international office network of the parent companies MHI and Siemens provides more than 300 group sites located in 190 countries.

SIEMENS VAI HERITAGE

Siemens VAI has 60 years of experience in metallurgical engineering and plant building. With its strong R&D focus, Siemens VAI has introduced a number of innovations that today form the backbone of global steelmaking. These can be traced to the company’s origin within the VÖEST steelworks – today voestalpine – in Linz, Austria, where in 1952 the first commercial oxygen steelmaking convertor process was developed. The new technology was called LD steelmaking – named after the cities Linz and Donawitz where it was first applied at company steelworks. Today, the process is generally known as basic oxygen steelmaking (BOS) or basic oxygen furnace (BOF).

In 1956, Voest-Alpine Industrieanlagenbau (VAI) was established to further develop and market this steelmaking technology on a global basis. The first order came from the Indian steel producer Rourkela. Continuous slab casting followed with the first straight mold caster introduced in 1968. After the acquisition of the Korf Engineering technology for smelting reduction, the first Corex unit was commissioned in 1989 in South Africa. In 1996, VAI acquired Fuchs of Germany, which significantly expanded the company’s electric steelmaking portfolio. In 1999, it added the metals division of the Norwegian Kvaerner group, which itself had acquired the U.K. Davy McKee company and Clecim of France, providing blast furnace and rolling mill expertise. Italian bar mill manufacturer Pomini was acquired in 2001. Four years later in 2005, Siemens of Germany took over the VA Tech Group, which included VAI. Under Siemens, the first Finex plant commenced operation in 2007 as a modification of a Corex plant by South Korean steelmaker Posco. Long products mill builder Morgan of the United States was acquired in 2008. In 2009, Siemens VAI jointly built the first endless strip production (ESP) plant for Arvedi of Italy as a further development of the Mannesmann Demag In-line Strip Production (ISP) plant originally installed at Arvedi’s Cremona steelworks. The year 2011 saw the integration of vatron, a mechatronics competence center in Linz, and in 2012 the U.S.-based furnace-product lines company FCE Drever was acquired. The latest acquisition was of the U.S. company Service Guide Inc. in 2013.

EMPLOYEES WORLDWIDE

MHMM HERITAGE

MHMM also has a long pedigree of serving the metals industries. The company was launched in October 2000 as a joint-venture between MHI and Hitachi Metals Machinery, Inc. It was originally named MHI-Hitachi Metals Machinery, Inc., and was changed to Mitsubishi-Hitachi Metals Machinery, Inc. (MHMM) in 2002. In 2004, a subsidiary of this company was founded in the United States, and the following year the U.S. company New Genecoat Inc. was acquired. In 2006, MHMM supplied a pickling line – tandem cold mill to Shougang Jingtang in China. One year later, a subsidiary company was established in Shanghai; and in 2010, Mitsubishi-Hitachi Metals Machinery South Asia Private Ltd. was set up in New Delhi. In 2013, the Ishikawajima Harima Jūkōgyō (IHI) Metaltech rolling mill business joined the group as well as Concast India. Also that year, a 100% holding in the Hasegawa Gear Works in Japan was obtained.

MHMM thereby acquired capabilities in product areas from continuous casting, hot and cold rolling, steel bar rolling up to downstream continuous annealing and galvanizing – all backed by in-house manufacturing and a strong sales network with engineering competence, particularly in Asia. As of April 2015, the company can refer to more than 2,200 plant references worldwide.

- Integrated mills

- Minimills

- Beneficiation plants

- Coking plants

- Sinter and pellet plants

- Blast furnaces

- Corex and Finex ironmaking plants

- Direct-reduction plants

- Converter steelmaking plants

- Electric steelmaking plants

- Stainless steelmaking plants

- Secondary metallurgical facilities

- Continuous casting plants

- Arvedi ESP plants (endless strip production)

- Strip-casting plants

- Plate and Steckel mills

- Hot-strip rolling mills

- Pickling plants

- Cold-rolling mills

- Nonferrous rolling mills

- Bar, wire rod, section, rail, tube and pipe mills

- Strip-processing and finishing lines

- Environmental plants

- Electrics and automation

- Metallurgical, consulting and financial services

- Modernization packages

The shareholders have appointed five directors to manage the new company as follows:

Yasukuni Yamasaki

Chief Executive Officer (CEO) and Chairman of the Board

Peter Schraut

Chief Financial Officer (CFO)

Heiner Röhrl

Chief Operating Officer (COO) – Upstream

Ryoichi Nishi

Chief Operating Officer (COO) – Downstream

Etsuro Hirai

Chief Technology Officer (CTO)

A NEW LOGO FOR A NEW COMPANY

THE NEW NAME

Following a lengthy and detailed name-selection process, it was decided to create a completely new brand name: Primetals Technologies. This would underline the opening of a new chapter in the joint company history. Primetals Technologies is a combination of the words prime, metals and technologies. It reflects a commitment to deliver the best (prime) and the most advanced technologies to produce the highest-quality metal products. The name prime also echoes the impressive technology legacies that all of the previously merged companies of the joint-venture partners have brought to the new organization.

THE LOGO

The logo of the new company consists of two separate arcs that symbolize the forging of two strong partners into a single, unified whole, but which reflects the differing intrinsic values, cultures and characteristics of the joint-venture partners. The split circle indicates forward motion focused on the future. The orange color signifies the temperature of the steel transition from the liquid phase to the solid phase – the point at which the outstanding technological strengths of Siemens VAI in the liquid phase meet the rolling and processing excellence of MHMM in the solid phase. The company name stands to the right of the circle.

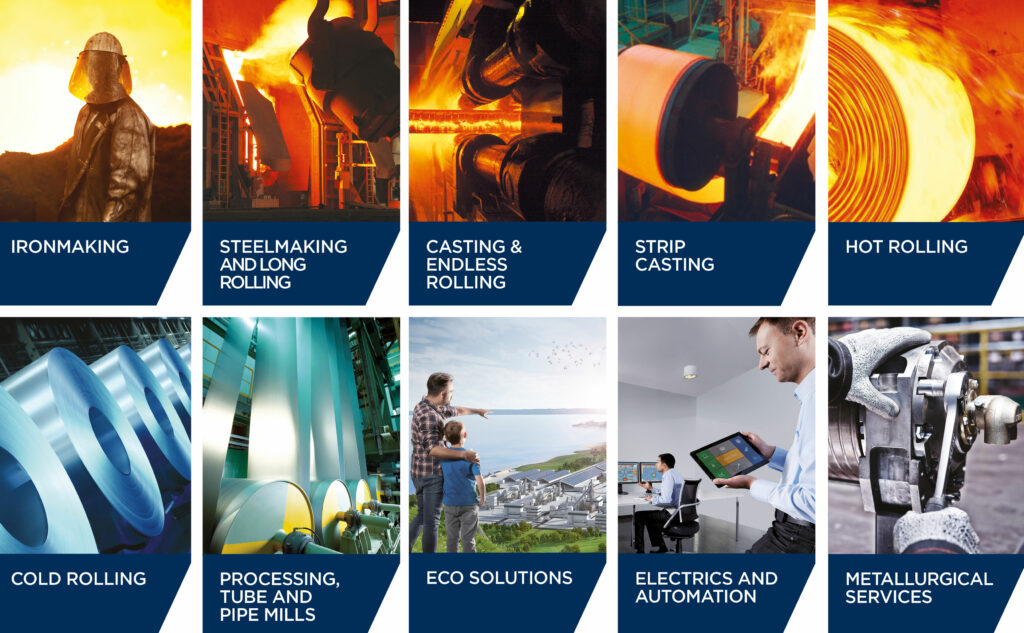

PORTFOLIO OF PRODUCTS AND SERVICES

On the basis of the experience and expertise acquired from the successful implementation of thousands of projects for the global metals industry, Primetals Technologies provides advanced and optimized solutions for integrated steelworks and minimills, for new and existing plants, and for all auxiliary facilities. The vertically integrated supply portfolio comprises mechanical equipment and mechatronic systems; drives, motors, automation, electrics and electronics; and utility supply and energy technologies. Primetals Technologies manufactures much of the core components used in its plant machinery at its own state-of-the-art factories and workshops. This underlines the company commitment to ensure that the machines and systems supplied meet the highest standards with respect to workmanship, reliability and durability. A key focus is placed on continuous improvement of products and processes, achieved in both incremental steps and by fostering a culture of innovation within the company. The results are seen in groundbreaking and pioneering product developments and solutions that enable customers to meet the increasingly stringent requirements for environmental standards and energy efficiency while reducing energy consumption and production costs. Primetals Technologies also has unrivaled experience in the modernization of metallurgical facilities. The objective is to ensure that machines and equipment operate at peak performance and in a cost-efficient manner throughout their entire lifetime. Through the installation of innovative technology packages and the integration of process-optimization systems, long-term value is created for customers. The results can be seen in significant improvements in productivity, product quality, plant flexibility and safety.Primetals Technologies thus offers a complete technology, product and service portfolio that ultimately comes to the benefit of producers. The company is dedicated to continuing its tradition of technological innovation and to creating the future of metals – as one.