On July 26, POSCO, a leading South Korean steel producer, and Primetals Technologies signed a Memorandum of Understanding (MOU) to develop a demonstration plant for hydrogen-based hot metal production (HyREX).

For the development of eco-friendly hydrogen-based hot metal production, collaboration across all sectors such as raw materials, engineering, and hydrogen is essential. Thanks to the collaboration between POSCO and Primetals Technologies, we will make use of leading technological knowledge during development and implementation”

Dr. KiSoo Kim

Head of Low Carbon Process R&D at POSCO

HyREX: Hydrogen-Based Direct Reduction

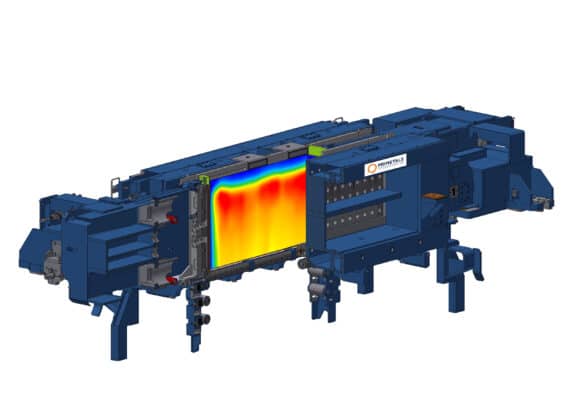

HyREX technology uses hydrogen to produce direct reduced iron (DRI) using sinter fines, avoiding agglomeration. An electric smelting furnace, or smelter, then melts the DRI. By circumventing the need for agglomeration steps and using hydrogen and a smelter to produce liquid hot metal, HyREX is environmentally friendly and cost-competitive.

From the Blast Furnace to HyREX

POSCO is driven to achieve carbon neutrality by 2050 and will continue evaluating the commercial feasibility of hydrogen-based hot metal production until 2030. The development and construction of a HyREX plant is part of POSCO’s goal to assess hydrogen-based direct reduction and implement solutions to achieve carbon neutrality by replacing blast furnaces to produce hot metal.

A Proven History of Collaboration

POSCO and Primetals Technologies have a history of collaboration. In 2007, POSCO was the first steel producer to successfully operate a commercial FINEX plant, an ironmaking process using fine iron ore. FINEX is an innovative technology developed by POSCO and Primetals technology, which enables low-cost production with the use of non-coking coal along with fine ore.

“We expect the HyREX technology to be a long-term and fundamental solution in many regions where it is difficult to use pellets. Let’s create a new success story together,” said Aashish Gupta, Executive Vice President at Primetals Technologies.

MORE INFORMATION

Click here to read the full press release, access contact details, and find other press resources.