Cooling Solutions & Circular Economy

Cooling Solutions & Circular Economy

Water is the element required to sustain life. It helps to balance the raw force of nature—Fire—with calm and restraint. Lava beaches, such as the ones found on the Canary Islands, are a manifestation of this balancing act, as they result from the ocean meeting the power of the Earth‘s hot, liquid core. In metals production, water plays a similar role. It equalizes the heat stemming from many upstream processes. It is also a catalyst and change agent—the medium without which many green technologies could not exist.

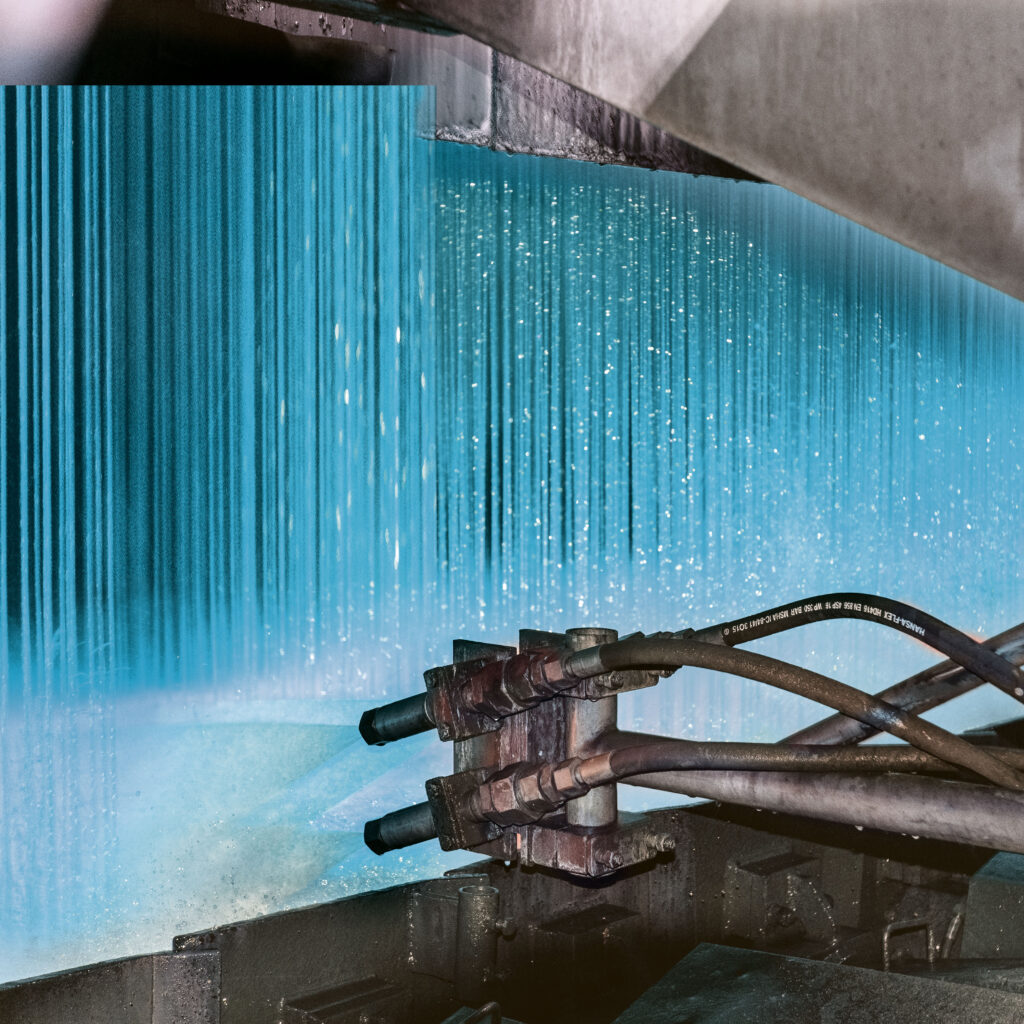

The transition to the electric steelmaking route has implications not only for iron- and steelmaking but also for later steps in the production chain. A change in the raw-material mix, for instance, a higher proportion of scrap, necessitates adjustments in continuous casting and at various cooling stages, so as to ensure that the surface quality of the cast and rolled products remains at the same high level previously achieved with integrated steel production. Water—correctly and thoughfully distributed—is the medium any advanced cooling strategy depends on. But the journey to green steel goes far beyond decarbonization and the shift to electric steelmaking.

Making metals production more sustainable also involves solutions geared toward realizing the circular economy—for example, By-Product Leaching plants and water-treatment plants, which Primetals Technologies has extensive experience with as some 200 plants have been sold to date. Heat recovery systems are equally relevant and often rely on water to absorb the enthalpy from hot waste gas and put the energy to use in a different area of the plant. In this process, water turns to steam and carries all the energy required to power additional plant equipment, leading to significant cost savings.

BY-PRODUCT LEACHING PLANTS

Thanks to advances in off-gas cleaning, steel producers have the technologies required to capture up to 99 percent of potentially harmful emissions stemming from their sinter and pelletizing plants, blast furnaces, converters, and other production units. One such technology—arguably the best available one—is the MEROS system. But while the primary result is clean air, the question remains: what is to be done with the substances that were removed from the off-gas? This is where By-Product Leaching plants come in: the world’s first was started up in 2020 and now recovers up to 90 percent of the valuable materials like iron, lime, and carbons for reuse and recycling. Just like MEROS, this innovation fulfills “best available technology” requirements. Learn more about By-Product Leaching in“Environmentally Fueled Innovation.”

ADVANCED COOLING SOLUTIONS

Thanks to continual development, the cooling solutions of Primetals Technologies have become even greener and more efficient, and also help producers to increase yield. Advanced cooling models precisely predict how much water will be required for at the cooling stages. Correctly controlled and distributed cooling also facilitates the transition to electric steelmaking, since the change in raw materials requires smart adjustments in later production steps to ensure the same end-product quality as formerly achieved via integrated steel production. The Power Cooling solution significantly reduces the need for expensive micro-alloying elements as it practically enables “alloying with water,” with higher cooling rates realizing the desired mechanical properties of the strip.

HEAT RECOVERY SYSTEMS

Energy savings are not only economically desirable as they lower overall production cost—they also contribute to making green steel a reality. Heat recovery systems should ideally be implemented in all areas of a steel plant that involve high-temperature processes. They often rely on water to absorb the enthalpy, move the energy away from the source, and make it usable for other purposes, such as powering additional plant equipment. One example that highlights the benefits of a high-end heat recovery system is a Primetals Technologies implementation at the site of Italian producer Acciaieria Arvedi. The system was designed to recover waste heat from the plant’s electric arc furnace and generates enough steam to power three pickling lines. Learn more about solutions powering energy efficiency at primetals.com.