The transformation of the global metals industry is underway. The steel industries focus on decarbonization, and reducing their environmental impact defines the path forward for sustainability. Green steel is a term that has come to represent sustainable initiatives and a focus on eco-friendly technologies. With producers already beginning their optimization and transition to green steel, reaching sustainable targets are no longer a theoretical possibility.

Ninety percent of the steel produced worldwide is in countries that have pledged carbon-neutral goals in the coming decades. As seen in the previous phases toward green steel, the potential for carbon emissions reduction is significant. Implementing the latest technologies and those currently in development will secure a new standard of production, redefining steel as a low-carbon and sustainable product for the globe.

Carbon Direct Avoidance

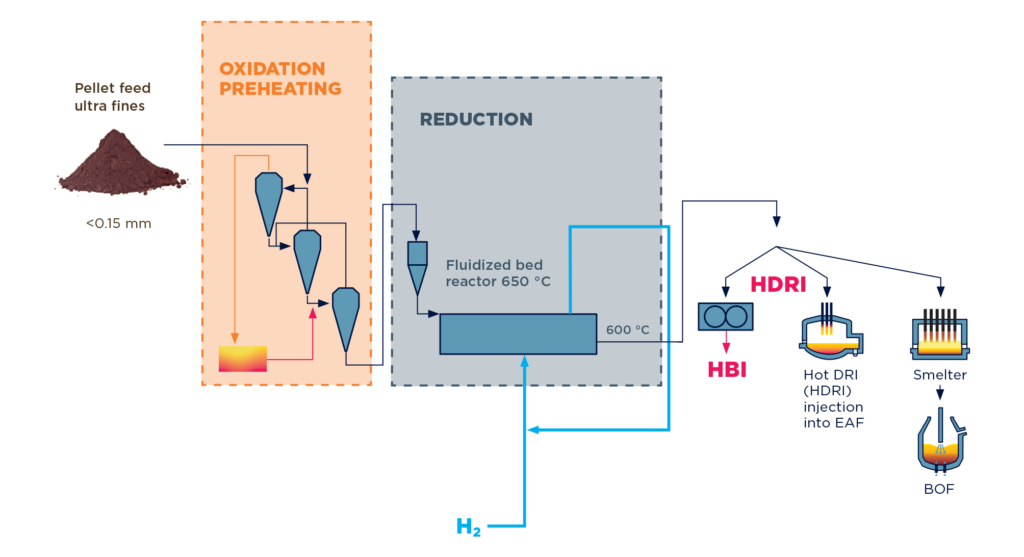

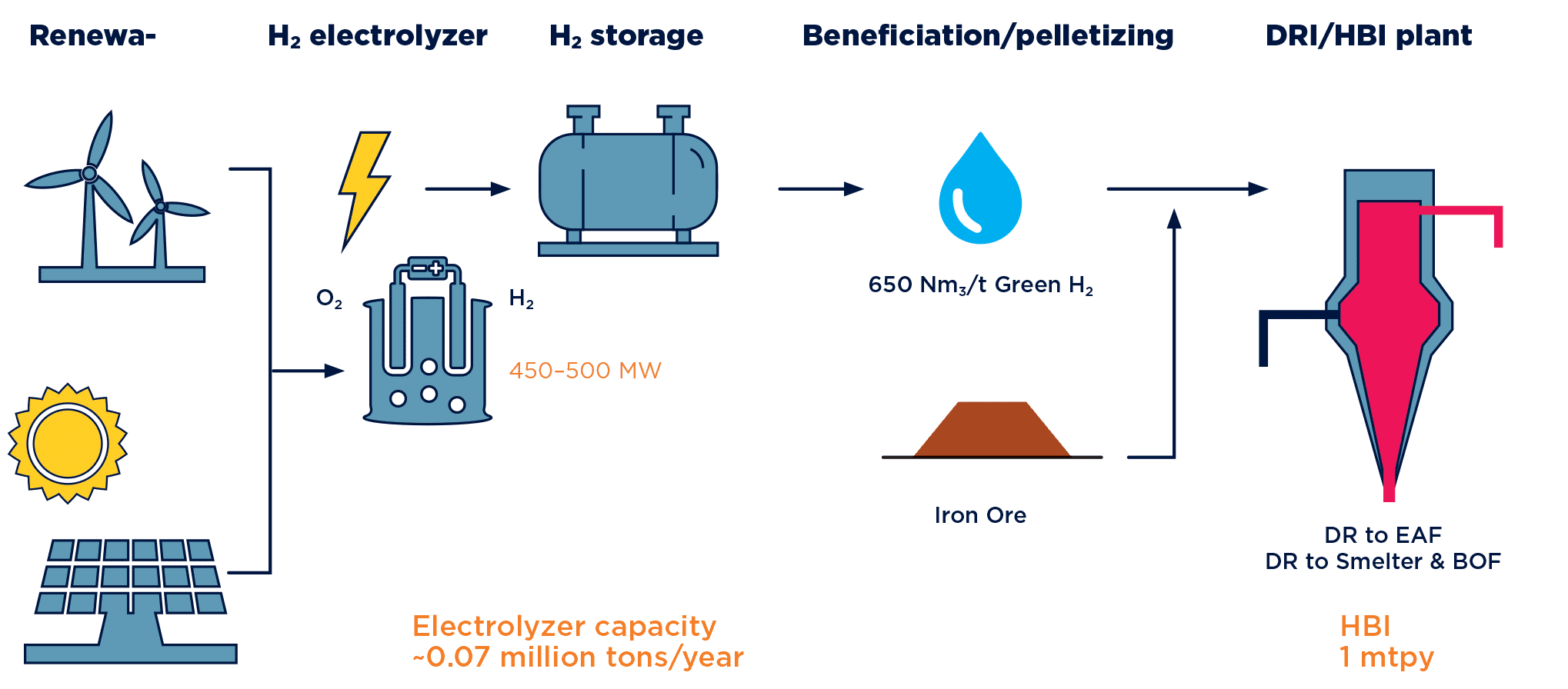

Green steel can be defined as an approach to metals production that focuses on the direct avoidance of carbon emissions altogether. Technologies for the direct reduction of iron ore represent one piece of the puzzle for avoiding carbon emissions. MIDREX direct reduction and hydrogen-based direct reduction processes, such as HyREX and HYFOR, avoid carbon emissions to reduce iron ore, utilizing hydrogen as the reducing agent. Hydrogen-based reduction with the Smelter powered by renewables leaves a manageable amount of subsequent carbon emissions on the way to the refining process. Hydrogen-based direct reduction of iron ore fines (HYFOR) also circumvents the beneficiation process and allows for the direct reduction of iron ore fines, sparing additional energy costs and emissions. Primetals Technologies is investigating an industrial demonstration plant in Linz, Austria, with voestalpine and the mining company Fortescue for this unique fluidized bed-based direct reduction technology—HYFOR—which combines with the Smelter solution to produce green pig iron. However, the impact of the iron and steel industry’s transformation will be felt in adjacent industries and help progress a global shift toward sustainability.

Hydrogen-based fine-ore reduction (hyfor)

or HYFOR, an essential technology defining the future of the steel industry.

Expanding Markets and Opportunities

The amount of energy required to produce steel is immense. Transferring the weight of production from a carbon-heavy production process to one based mainly on electrical energy may appear daunting, but it presents exceptional opportunities for the steel industry. The expansion and application of renewables to produce green energy will require revitalization and expansion of the energy sector in favor of new technologies, which require vast amounts of steel. Expansion of renewable energy technologies implies that, amid the energy transition, steel producers can manufacture the steel that will create the foundation for their sustainable future. Moreover, digital technologies, combined with waste heat recovery and gas recycling, encourage energy preservation, providing exceptional opportunities to keep energy costs low.

The energy transition

The market for renewable energy is set to expand to support heavy industry alongside the hydrogen economy. Hydrogen plays a key role in the chemical processes associated with green steel. Already, producers are focused on incorporating hydrogen production into their plant infrastructures—e.g., H2Future, a pilot facility to test the application of hydrogen in steel production, located at voestalpine’s steelworks in Linz, Austria. The focus on these expanding economies also includes recycling previously wasted carbon emissions. Partnering with LanzaTech, Primetals Technologies helped to establish a gas-fermentation “Steelanol” plant at ArcelorMittal’s facility in Gent, Belgium, recycling blast-furnace waste gas into bioethanol.

The future of sustainable metals is defined by green steel technologies that reshape the landscape of steel production, pioneering zero-waste, carbon-neutral heavy industry.

The Future of Sustainable Metals

Converting waste into valuable by-products, recovering raw material, contributing to the circular economy, and becoming a flagship zero-waste carbon-neutral industry—the future of sustainable metals is defined by green steel technologies that reshape the landscape of steel production. As one of the most sustainable products in the world, steel is synonymous with strength, endurance, and recyclability. It is only just that the metals industry is behind the global production of steel for expanding markets that will reshape a sustainable society and forge a path toward carbon neutrality.

The steel industry is not alone in its pursuits. Primetals Technologies, leveraging its position as part of the Mitsubishi Heavy Industries Group (MHI), is also expanding carbon capture, utilization, and storage to the steel industry. Using MHI’s unique KS-1 solvent, the Kansai Mitsubishi Carbon Dioxide Recovery (KM CDR) process has been applied to the energy sector. Today, it is finding new applications as specialists at Primetals Technologies explore applications for plants operating carbon-heavy integrated routes. The future will see industrial-scale carbon capture and storage technology rollouts at steel plants worldwide. An industry-wide shift toward electric steelmaking and hydrogen-based production will be supplemented by carbon capture utilization and storage to define a carbon-neutral metals industry that has achieved the new standard of green steel. l

Salzgitter Low CO2 Steelmaking: SALCOS

Salzgitter AG has begun investing in the transformation of an integrated 6 MTPY steel plant to a hydrogen-based DRI and electric arc furnace plant. Producing green hydrogen utilizing renewable energy and shifting production to direct reduction to replace the blast furnace, the first phases of the project will see a reduction of emissions by 30 percent and up to 95 percent by 2033.

GravitHy

A company comprised of EIT InnoEnergy, Engie New Ventures, Plug Power, Forvia, Groupe IDEC, and Primetals Technologies launched GravitHy in 2022 with the goal of becoming a sustainable green ironmaking company in France. GravitHy is focused on producing green direct reduced iron and reducing emissions by as much as 95 percent.

Acciaieria Arvedi

Achieving carbon-neutral targets years in advance of initial goals, Arvedi has become the first steel mill certified with net-zero carbon emissions in 2022. Arvedi continues to invest in their existing electric steelmaking plant and finding room for improvement to maintain their carbon neutrality for scope 1 and 2 emissions.